- 35kHz 1200watt Vibrating-Screen Transducer

- This is for Vibrating-Screen (Built in Type)

- Φ35mm P8 Ceramic Ring x 2 pcs

- more capacitance 4400pF

- low Impedance 6.0Ω

- Wide Bandwidth: 36kHz ~ 38kHz

-

-14%

-

-14%

- 35kHz 1200watt Vibrating-Screen Transducer

- This is for Vibrating-Screen (External)

- Φ35mm P8 Ceramic Ring x 2 pcs

- more capacitance 4400pF

- low Impedance 6.0Ω

- Wide Bandwidth: 36kHz ~ 38kHz

-

-37%

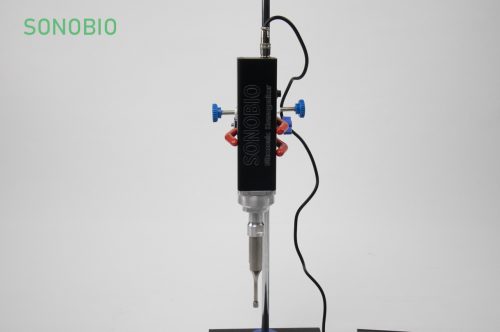

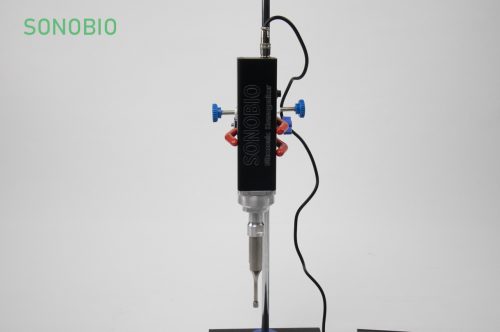

- Processing Capacity: 0.3-500ml

- Titanium Alloy Longlife Design: Probe size: Φ3mm, Φ6mm, Φ8mm

- Frequency: 28-32KHz Automatic Frequency Scanning

- Power: DC 12-24V | AC 110-220V

-

-30%

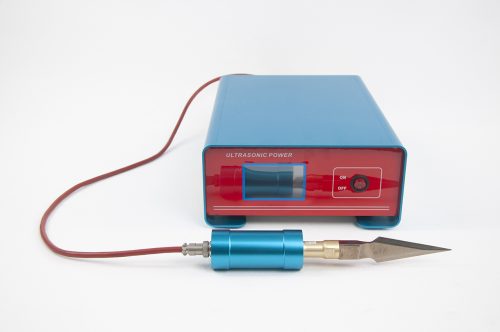

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc. PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials. FUNCTIONS: Automatic resonance point, automatic frequency sweep tracking in the frequency range of 19-26KHZ. Automatic amplitude compensation, which automatically works at the optimal frequency point and output point according to the fluidity of the sample. Independent on/off pulse with three modes of continuous use, pulse and timed continuous ultrasound. NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape.

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc. PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials. FUNCTIONS: Automatic resonance point, automatic frequency sweep tracking in the frequency range of 19-26KHZ. Automatic amplitude compensation, which automatically works at the optimal frequency point and output point according to the fluidity of the sample. Independent on/off pulse with three modes of continuous use, pulse and timed continuous ultrasound. NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape. -

-8%

- 15kHz Ultrasonic Welding Booster for Horn Amplifier.

- Hard Steel Materials

- Booster Gain: 1:2.5

- Please contact our sales before placing order

- Titanium & Solid Mount Titanium Boosters also Available! Call for Availability.

-

-8%

- 20kHz Ultrasonic Welding Booster for Horn Amplifier.

- Aluminium Alloy

- Booster Gain: 1:1.25

- Titanium & Solid Mount Titanium Boosters also Available! Call for Availability.

-

-8%

- 20kHz Ultrasonic Welding Booster for Horn Amplifier.

- Hard Steel Materials

- Booster Gain: 1:3

- Please contact our sales before placing order

- Titanium & Solid Mount Titanium Boosters also Available! Call for Availability.

-

-42%

- 20kHz Branson Ultrasonic Welding Booster.

- Aluminium Alloy

- Booster Gain: 1:1.1

- Titanium & Solid Mount Titanium Boosters also Available! Call for Availability.

-

-22%

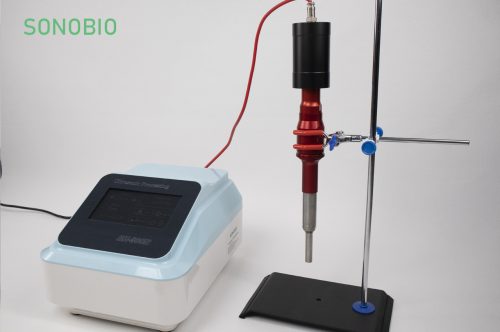

【Fácil de usar】 homogeneizador ultrasónico Pantalla táctil a color de 7 '', 3 modos de trabajo, operación programable. La interfaz fácil de usar permite la monitorización en proceso de variables clave, incluyendo tiempo, potencia, energía, temperatura y progreso del experimento. 【Automatización】 Circuito PCB auto barrido diseñado por sí mismo con frecuencia y control automático de potencia, funcionamiento automático y protección automática. 【Sonda de titanio duradera】 Varilla de amplitud aleación titanio alta pureza que trabaja al máximo a una temperatura alta máxima 1112°F resistente a ácidos y álcalis. 【Amplia gama aplicaciones】 Preparación muestra, ruptura células, dispersión nanopartículas , mezcla homogeneización , ADN lisis celular extracción proteínas. 【Garantía DE DOS AÑOS】 Calidad garantizada.

【Fácil de usar】 homogeneizador ultrasónico Pantalla táctil a color de 7 '', 3 modos de trabajo, operación programable. La interfaz fácil de usar permite la monitorización en proceso de variables clave, incluyendo tiempo, potencia, energía, temperatura y progreso del experimento. 【Automatización】 Circuito PCB auto barrido diseñado por sí mismo con frecuencia y control automático de potencia, funcionamiento automático y protección automática. 【Sonda de titanio duradera】 Varilla de amplitud aleación titanio alta pureza que trabaja al máximo a una temperatura alta máxima 1112°F resistente a ácidos y álcalis. 【Amplia gama aplicaciones】 Preparación muestra, ruptura células, dispersión nanopartículas , mezcla homogeneización , ADN lisis celular extracción proteínas. 【Garantía DE DOS AÑOS】 Calidad garantizada. -

-37%

- Capacidad de procesamiento: 0.3-500ml

- Diseño de aleación de titanio de larga duración: Tamaño de la sonda: Φ3mm, Φ6mm, Φ8mm

- Frecuencia: Escaneo automático de frecuencia 28-32KHz

- Potencia: DC 12-24V | AC 110-220V

-

-28%

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc. PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials. FUNCTIONS: Rotary Ultrasonic Cutter is a large amplitude type where the blade vibration amplitude is made larger than conventional models. With a 42 mm diameter cylindrical shape, the model is easy to be mounted on automated machinery, industrial robots and plotters. It is best suited for cutting and punching processing of 3D parts by mounting on industrial robots, in addition to processing of sheets and punching. NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape.

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc. PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials. FUNCTIONS: Rotary Ultrasonic Cutter is a large amplitude type where the blade vibration amplitude is made larger than conventional models. With a 42 mm diameter cylindrical shape, the model is easy to be mounted on automated machinery, industrial robots and plotters. It is best suited for cutting and punching processing of 3D parts by mounting on industrial robots, in addition to processing of sheets and punching. NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape. -

-27%

- CE Certified.

- A high-tech device used for controlling ultrasonic equipment via a user-friendly touch screen interface.

- Build in DSP chip control circuit, Japan's capacitor, and high power output amplifier.

- Integrated full digital integrated circuit and the high performance anti-interference processor.

- Full-automatic frequency scanning, full-automatic frequency tracking, great working bandwidth.

- The output power is automatically adjusted according to the load, or maunally.

- Automatic error reporting, and prompts the fault display problem.

- Auto protection functions of transducer failure, overheating and load over current.

-

-6%

Ultrasonic food cutter minimize product sticking and deformation, ensuring cleaner cuts and maintaining product aesthetics, especially in layered foods. They reduce waste by cutting with precision, effectively slicing inclusions like nuts and dried fruits without displacement, even in soft matrices. Ultrasonic cutting technology enables faster processing speeds, easily integrates into existing production lines, and provides consistent results in food cutting applications. Designed for low maintenance, ultrasonic cutters reduce downtime by eliminating frequent cleaning needs, especially when cutting sticky products.

Ultrasonic food cutter minimize product sticking and deformation, ensuring cleaner cuts and maintaining product aesthetics, especially in layered foods. They reduce waste by cutting with precision, effectively slicing inclusions like nuts and dried fruits without displacement, even in soft matrices. Ultrasonic cutting technology enables faster processing speeds, easily integrates into existing production lines, and provides consistent results in food cutting applications. Designed for low maintenance, ultrasonic cutters reduce downtime by eliminating frequent cleaning needs, especially when cutting sticky products. -

-43%

No pollution to the samples. Fast processing time. Simple mechanical structure. More flexible with multiple combinations.

No pollution to the samples. Fast processing time. Simple mechanical structure. More flexible with multiple combinations. -

-35%

No pollution to the samples. Fast processing time, simultaneous processing of 4 channels. Simple mechanical structure. More flexible with multiple combinations.

No pollution to the samples. Fast processing time, simultaneous processing of 4 channels. Simple mechanical structure. More flexible with multiple combinations.