Imagine a tool that revolutionizes the way industries inspect and maintain their equipment. An Ultrasonic Probe that is both efficient and non-intrusive, capable of ensuring the highest standards of quality without damaging the materials. This isn’t just a product of imagination – it’s a reality, thanks to ultrasonic probes.

What is an Ultrasonic Probe?

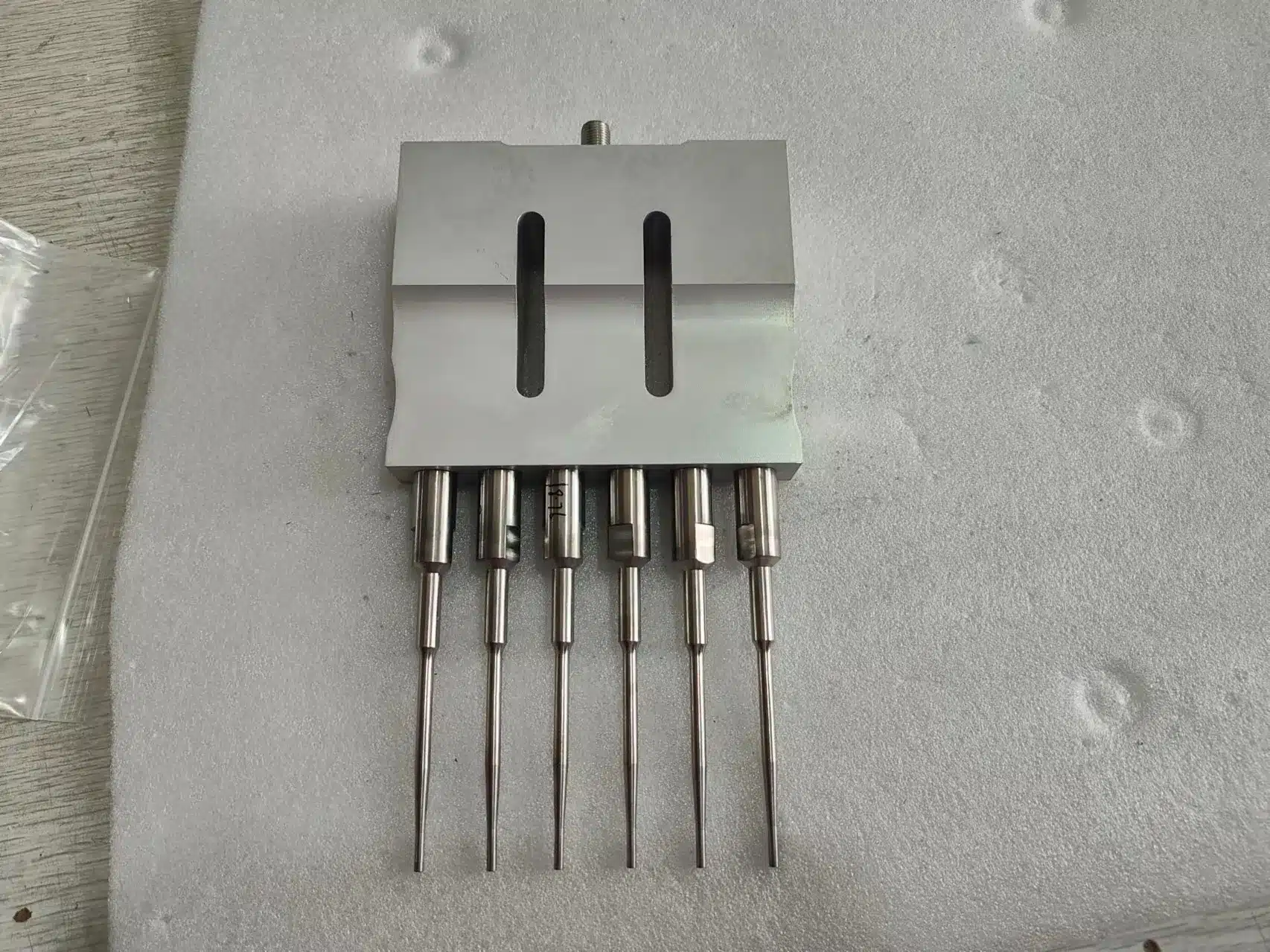

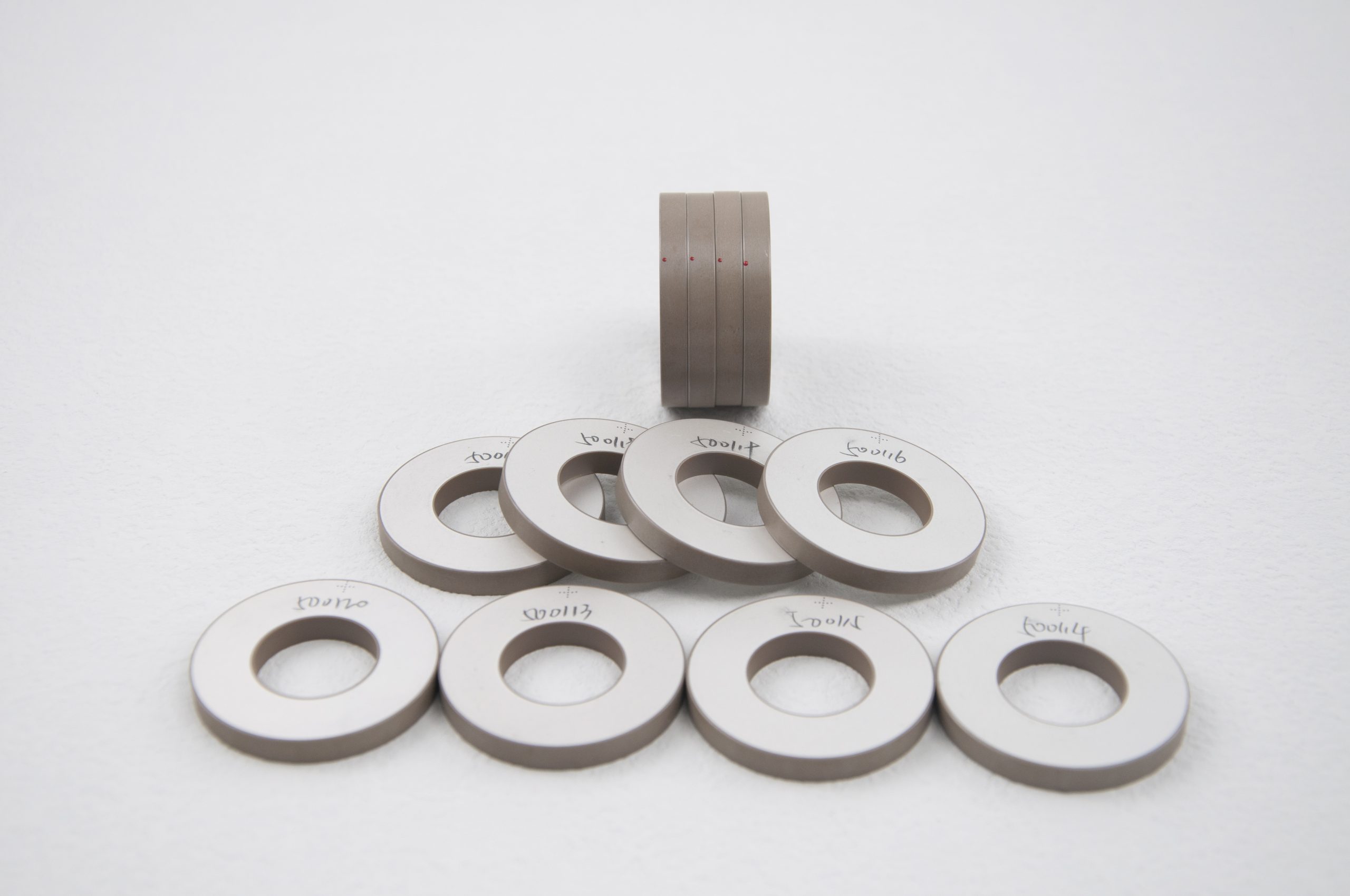

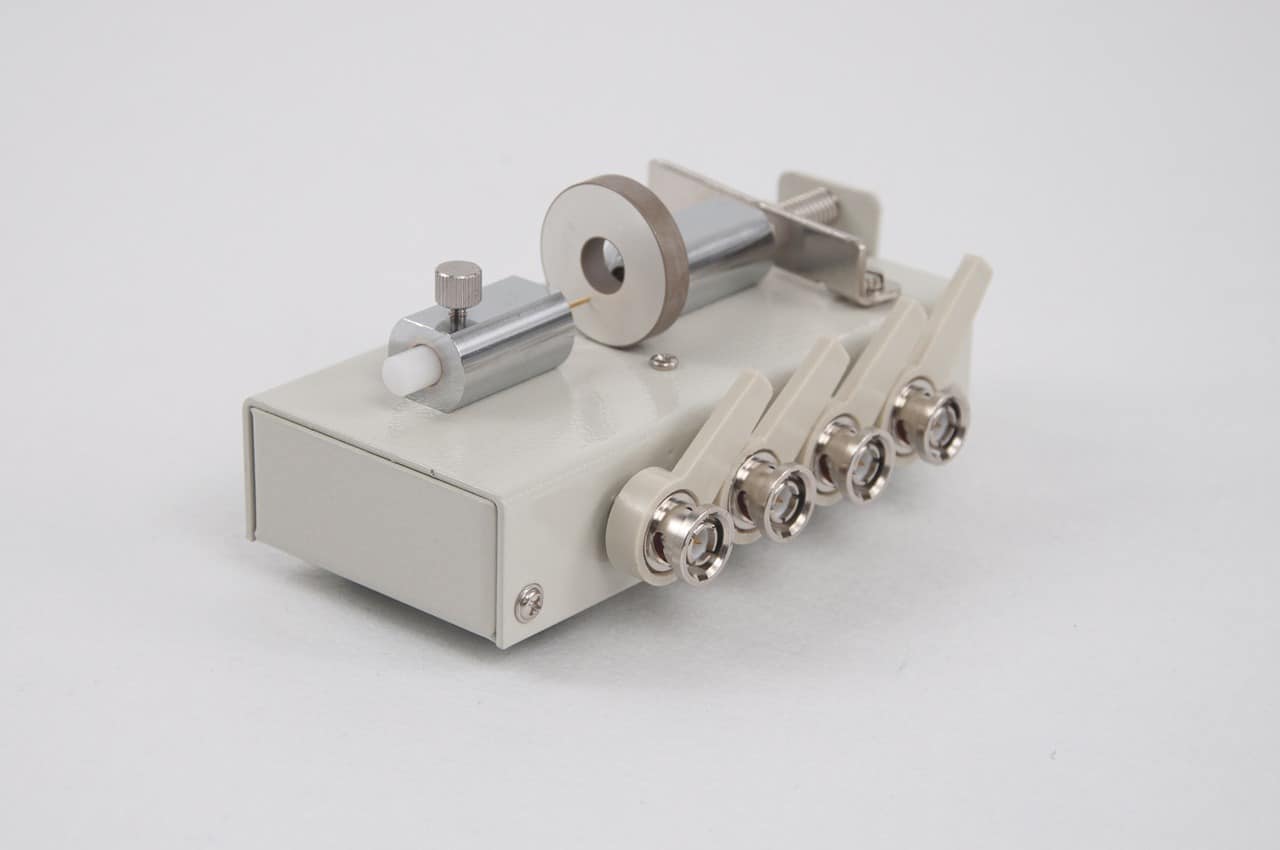

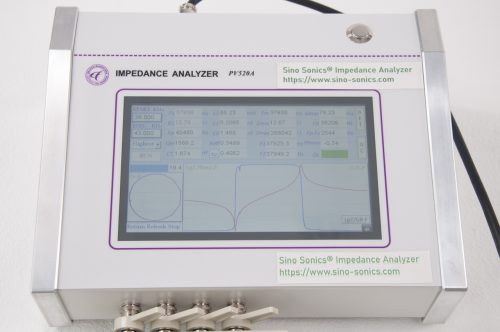

An ultrasonic probe, also referred to as an ultrasonic transducer, is an innovative device used in various industries to detect flaws and measure material thickness. By emitting high-frequency sound waves, these probes can identify irregularities and variations within materials, which could indicate potential issues.

How Ultrasonic Probes Work

The process is fascinating. When the probe is applied to a material, it emits sound waves that penetrate the surface. These waves are then reflected back to the probe, and the time they take to return is measured. This measurement helps determine the thickness of the material and identify any internal defects, all without causing any harm to the material itself.

In conclusion, ultrasonic probes do more than just inspect; they play a crucial role in maintaining quality and safety across various industries. Their capacity for accurate and non-destructive testing renders them an invaluable asset in the technology-driven world of today.

For more information, and how to choose, click here.