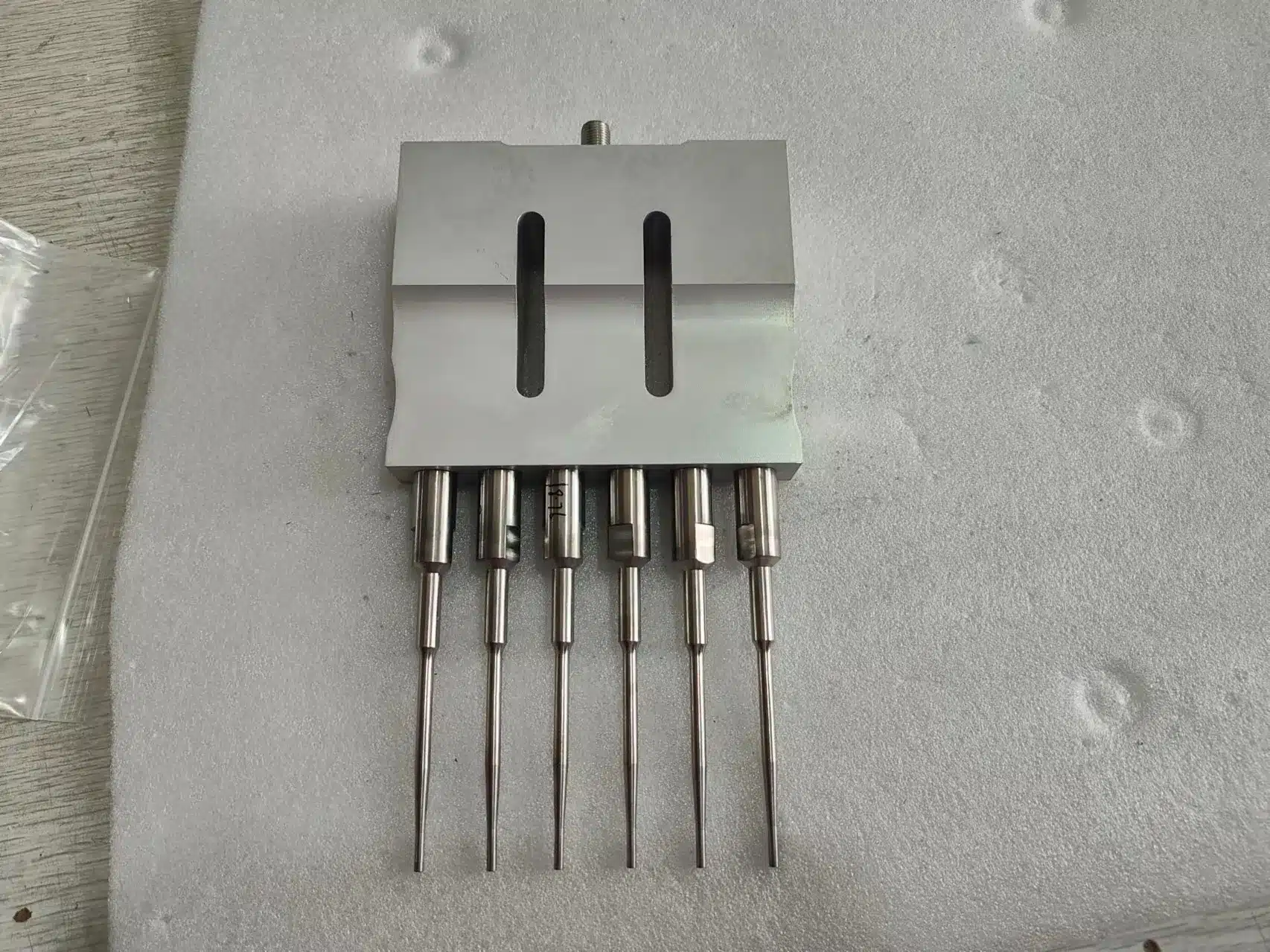

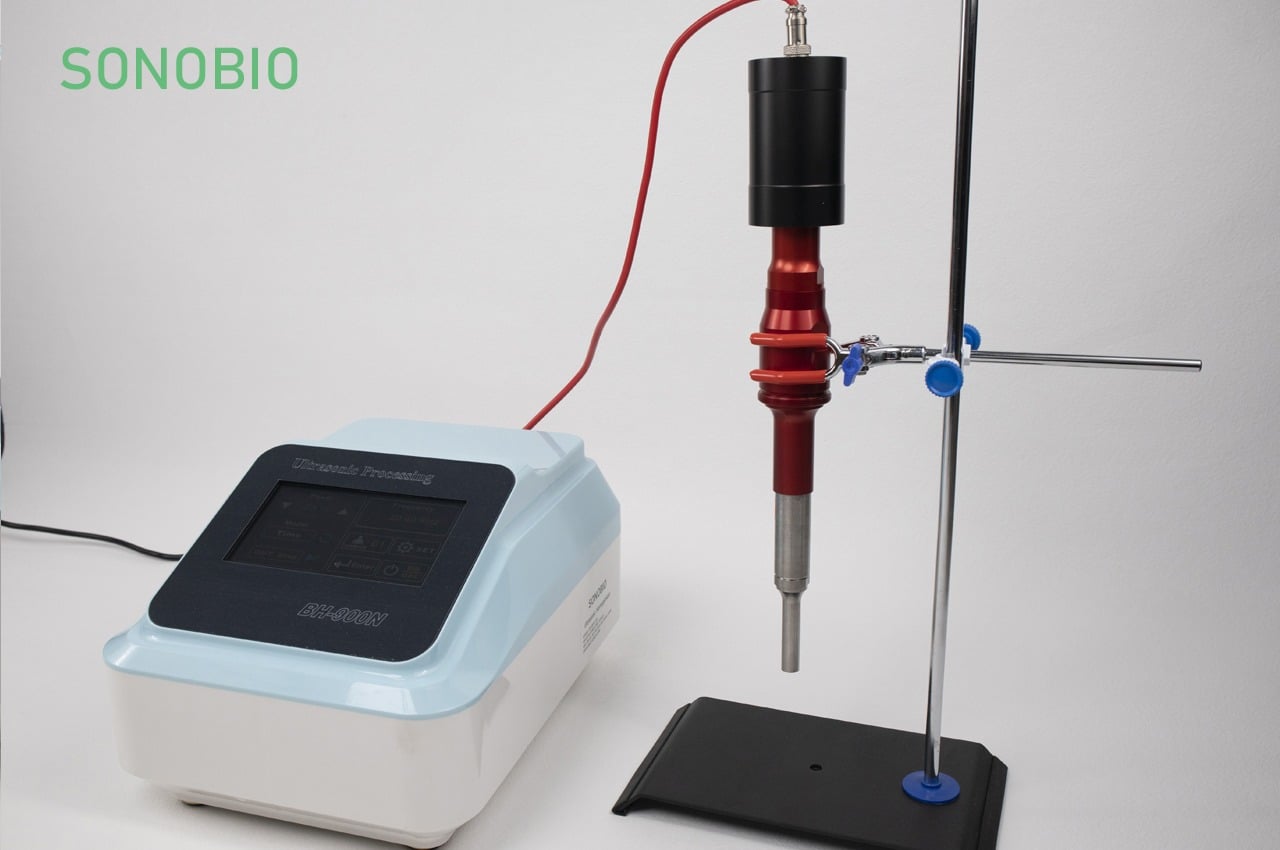

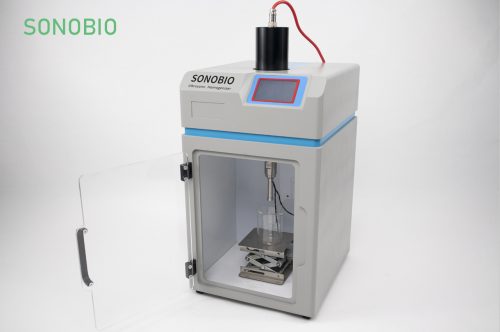

Ultrasonic homogenizers are essential tools in industries ranging from biotechnology to nanomaterial dispersion. At Sino Sonics, we specialize in high-performance ultrasonic equipment, including ultrasonic probes (also known as horns), which are crucial for efficient energy transmission into liquid samples. However, one of the major challenges associated with ultrasonic probes is cavitation erosion—a process that gradually degrades the probe tip over time.

What Causes Cavitation Erosion?

Ultrasonic probes act as mechanical amplifiers, increasing the vibration amplitude generated by the transducer and transmitting ultrasonic waves into liquids. These waves create alternating cycles of compression and expansion, producing microscopic cavitation bubbles. When these bubbles collapse, they generate intense shock waves, acoustic streaming, and localized temperature spikes, leading to the gradual breakdown of the probe tip.

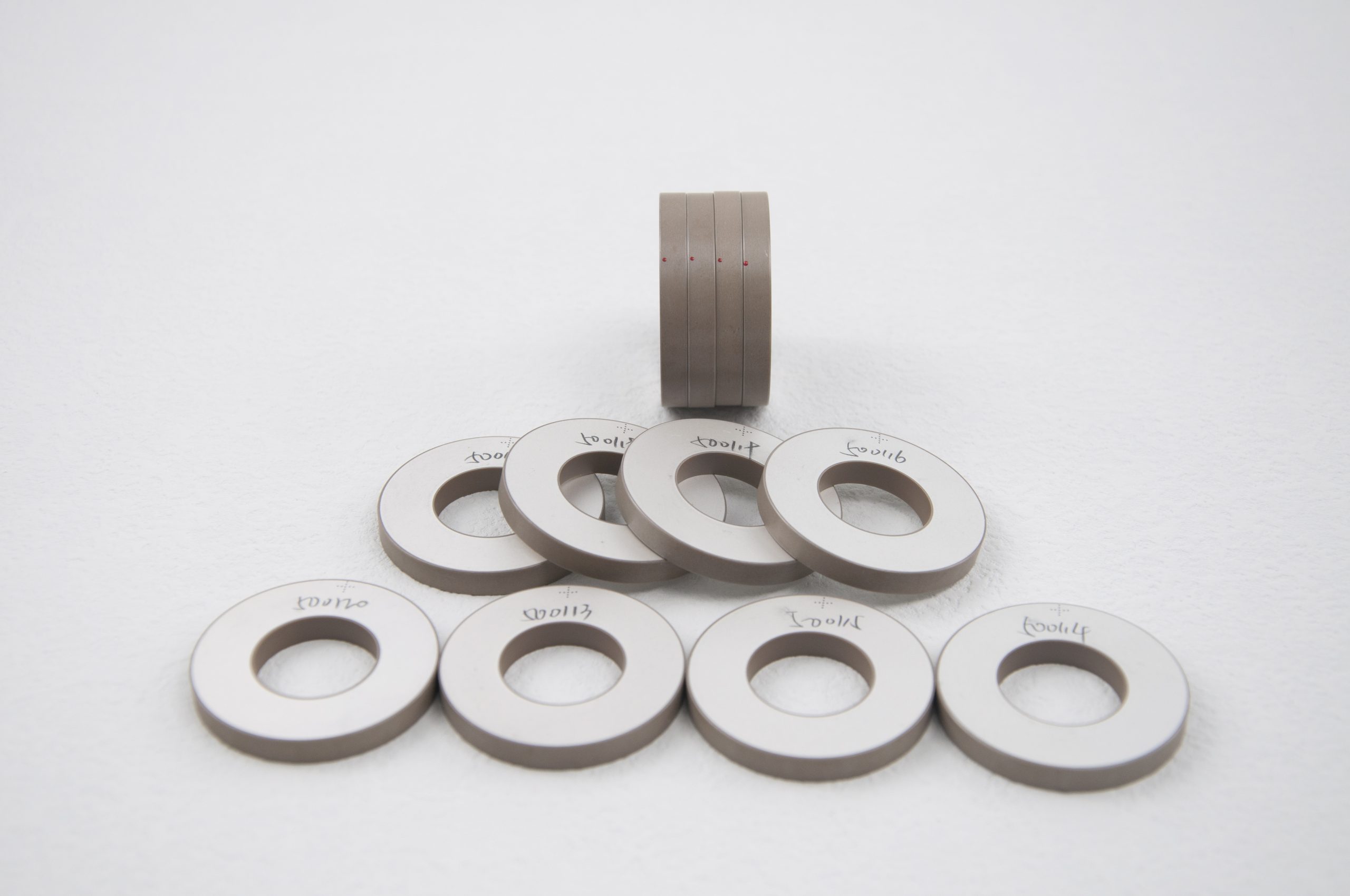

Despite being manufactured from Ti-6Al-4V titanium alloy, known for its high strength, corrosion resistance, and excellent ultrasonic transmission properties, even the most durable probes eventually suffer from cavitation-induced wear. No solid material is immune to cavitation’s destructive power, making proper probe maintenance crucial.

How Cavitation Erosion Affects Performance

As cavitation erosion progresses, the surface of the probe tip becomes rougher, which negatively impacts energy transmission efficiency. The roughened tip disrupts uniform energy distribution, leading to decreased ultrasonic effectiveness. Without intervention, an eroded probe may eventually fail to function optimally, affecting sample processing efficiency and experimental reproducibility.

Why Water Accelerates Probe Erosion

One key factor influencing cavitation intensity is liquid surface tension. Water, commonly used in ultrasonic applications, has a high surface tension that intensifies cavitation, causing probe tips to erode up to five times faster than when using organic solvents. While water is an excellent medium for ultrasonic processing, users should be aware of its impact on probe longevity.

Extending the Life of Your Ultrasonic Probe

At Sino Sonics, we provide expert recommendations to maximize probe lifespan and maintain optimal performance:

- Regular Tip Inspection & Maintenance: Light erosion can be mitigated by polishing the tip with fine abrasive paper to restore a smooth surface.

- Precision Machining: If the tip is severely eroded, a trained machinist may carefully remove the damaged area, ensuring minimal material loss to maintain the probe’s resonance frequency.

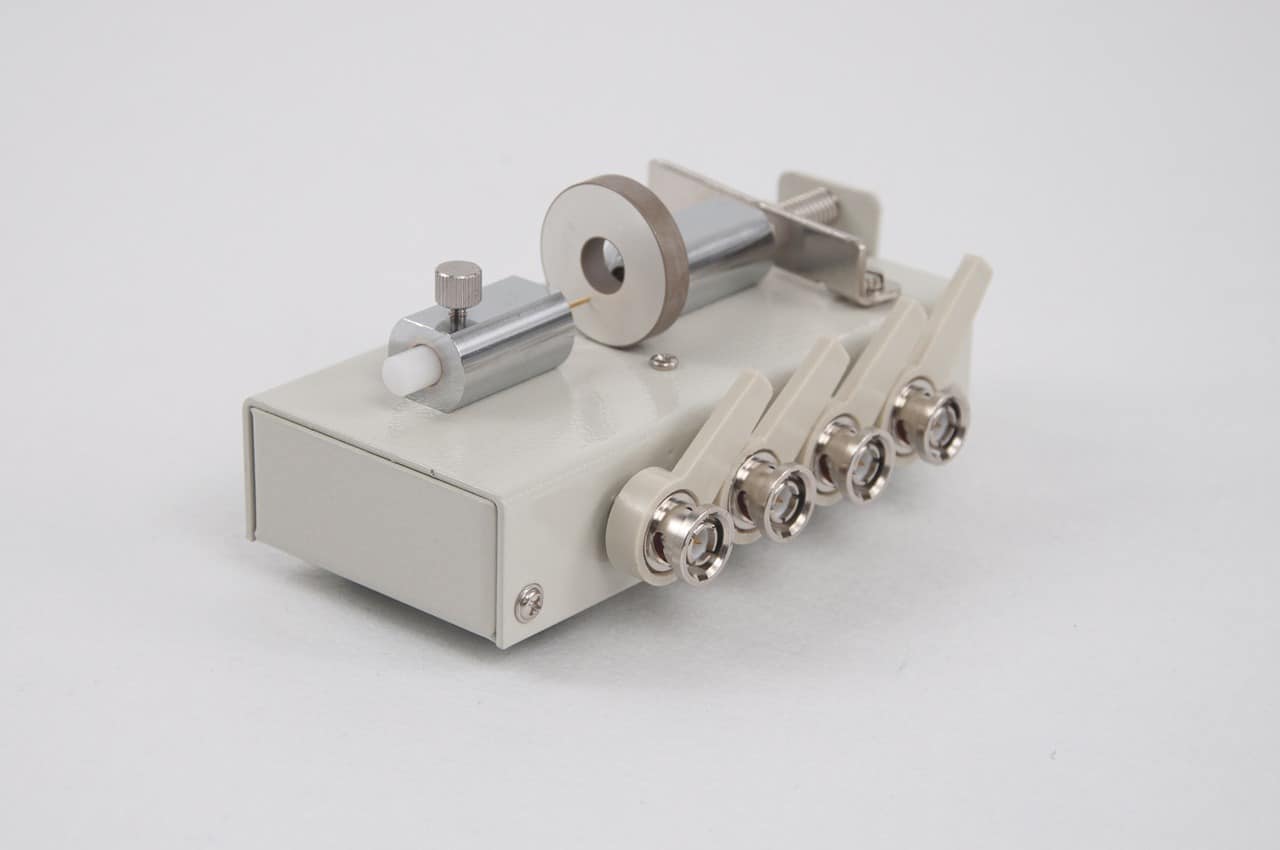

- Proper Frequency Testing: To check probe resonance, set your ultrasonic power supply to 100% amplitude (40% for microtips) and observe the power output. A healthy probe should read below 15W (5W for microtips) when activated in air. Higher readings indicate probe degradation, requiring replacement.

- Optimized Liquid Selection: Consider alternative solvents with lower surface tension to reduce cavitation intensity and slow down erosion.

Can Coatings or Reinforced Tips Prevent Erosion?

Over the years, researchers have tested numerous coatings, including ceramics, sapphire tips, and wear-resistant layers, to extend probe lifespan. Unfortunately, these coatings typically last only a few minutes before shattering or detaching due to extreme ultrasonic stress. Thus, while experimental solutions exist, there is currently no foolproof method to fully prevent cavitation erosion.

Sino Sonics: High-Performance Ultrasonic Solutions

At Sino Sonics, we engineer ultrasonic homogenizers and probes designed for durability and efficiency. Our high-grade Ti-6Al-4V probes are optimized to withstand rigorous cavitation conditions, ensuring superior performance in laboratory and industrial applications.

By following proper maintenance practices and selecting the right operating conditions, users can significantly extend probe lifespan and maintain consistent ultrasonic performance.

For expert advice on ultrasonic homogenization and to explore our range of high-quality ultrasonic accessories, contact Sino Sonics today!