Working principle

The working principle of ultrasonic cutting machine is completely different from traditional cutting machine. It uses the energy of ultrasonic, to melt the local heating of the material to be cut, so as to achieve the purpose of cutting the material. Therefore, ultrasonic cutting does not require a sharp edge. Nor does it require a lot of pressure, so that it will not cause the edge of the cut material to collapse and damage. At the same time, due to the ultrasonic vibration of the cutting knife. The friction resistance is very small, and the cutting material is not easy to stick to the blade. It is especially suitable for cutting viscous and elastic materials, frozen materials (such as food, rubber, etc.) or objects that are inconvenient to pressurize. Ultrasonic cutting also has a great advantage, that is, while cutting, the cutting part has a fusion effect. The edges of the cutting part are intact to prevent loose tissues of the cutting material (such as flashing of textile materials). The use of ultrasonic cutting machine can also be expanded, such as digging holes, shoveling, scraping paint, carving, cutting, etc

Working Process

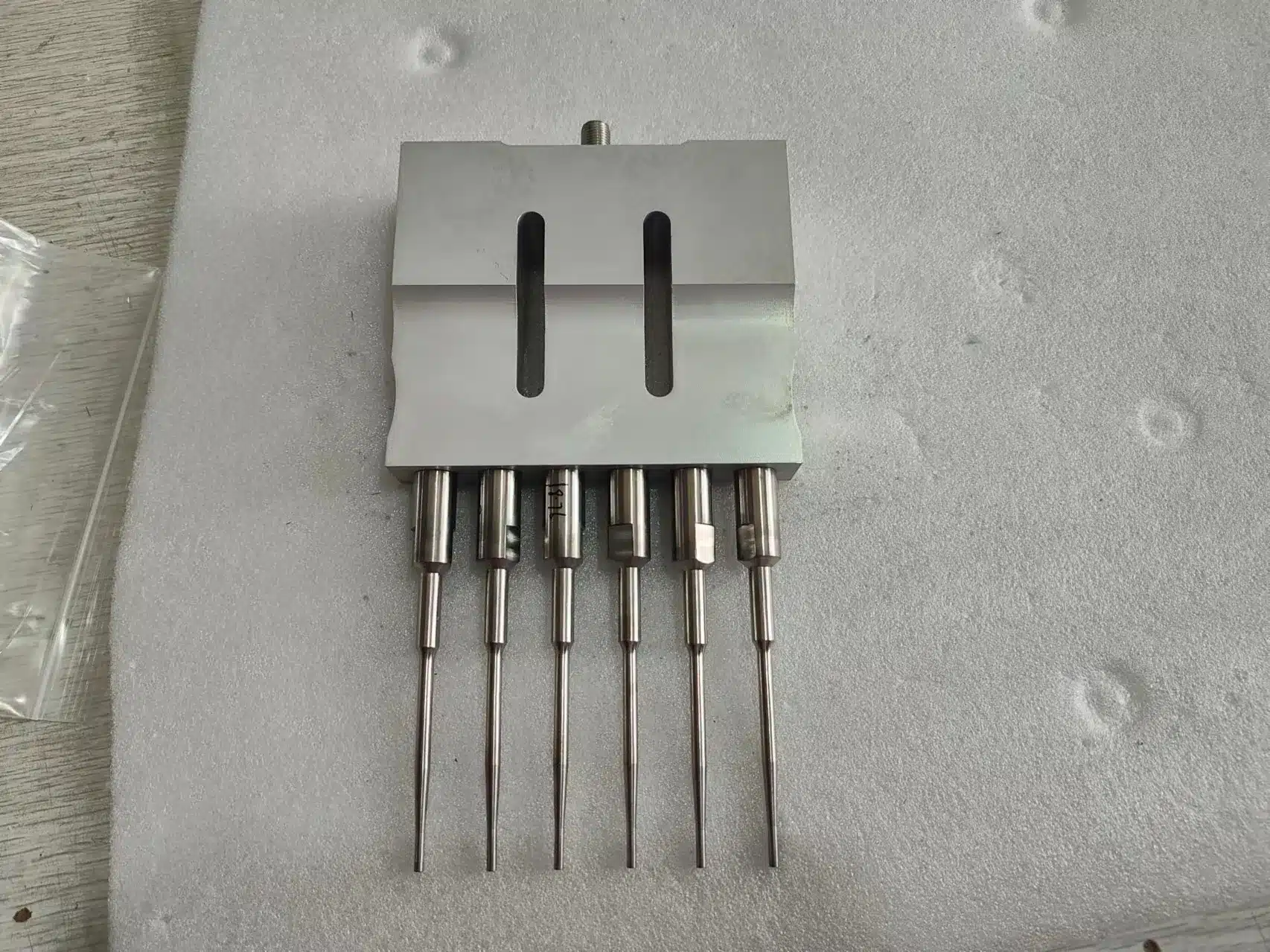

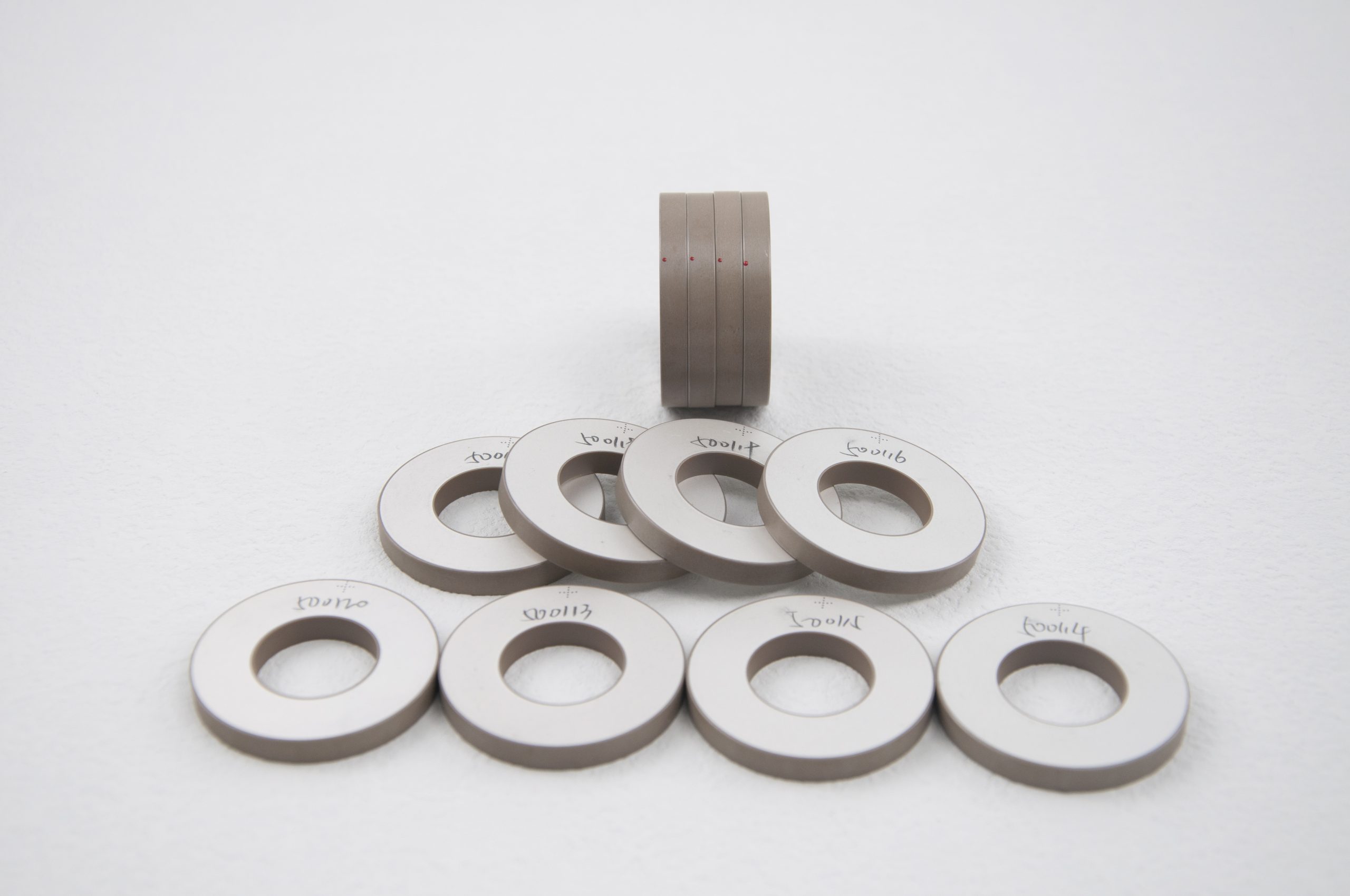

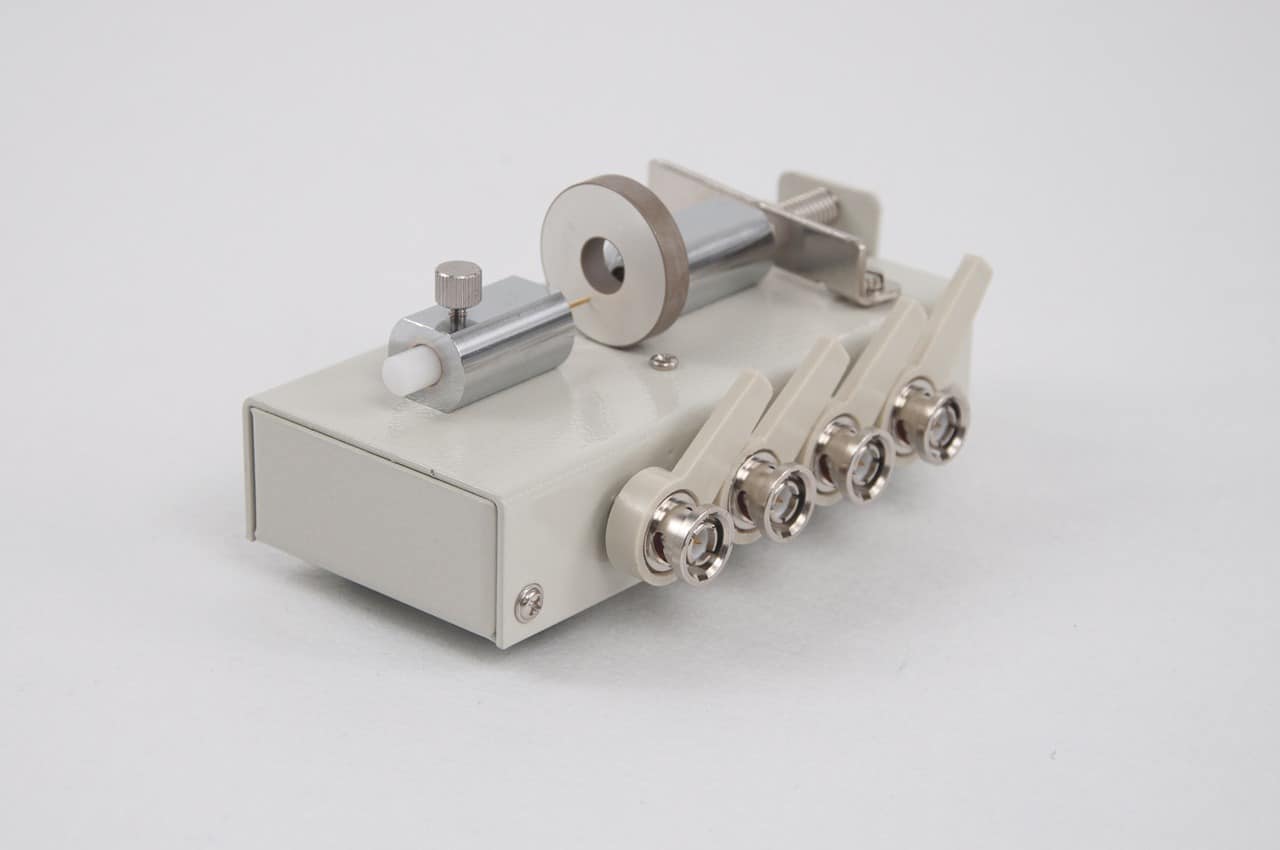

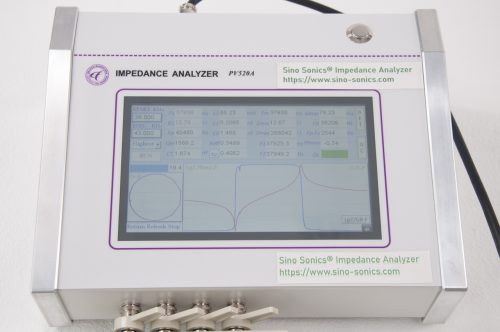

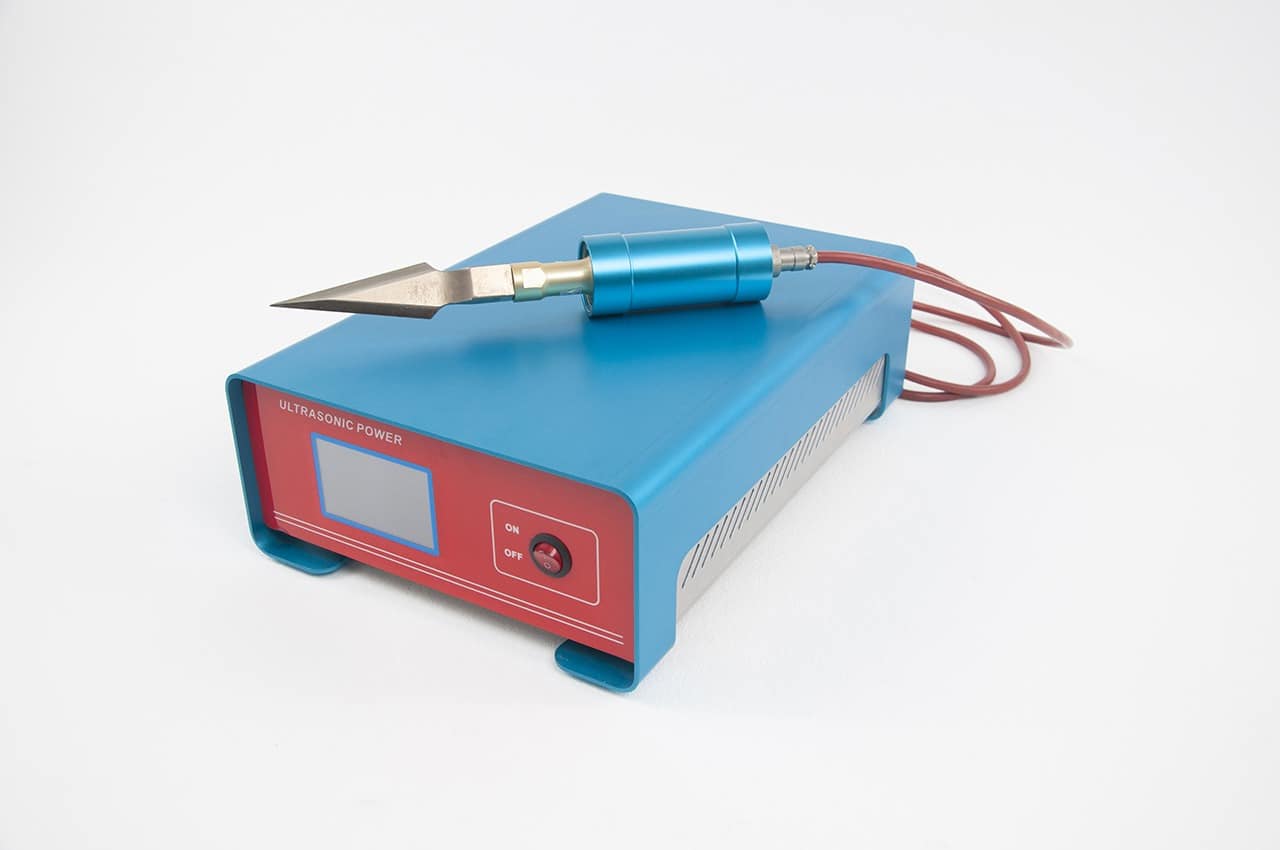

The ultrasonic cutter operates through a combination of key components. It comprises a “transducer” responsible for generating vibration and an “oscillator” that propels the transducer. Within the transducer, a piezoelectric element is employed. When voltage is applied, this element displaces the transducer marginally, typically by a few micrometers. The application of voltage at intervals produces vibration. Objects possess unique frequencies that render them stable and easily resonant. By applying an external force that matches this special frequency, a minor force can yield substantial vibration. This phenomenon is termed resonance.

In the ultrasonic cutter, the piezoelectric element generates a force that resonates through the entire body, from the transducer to the blade tip, resulting in substantial vibration at the tip. The oscillator intermittently provides voltage to resonate and drive the transducer. Employing a component known as the horn, which tapers the cross-sectional area from the piezoelectric element to the blade tip, augments the vibration significantly.

This process is instrumental in the operation of an ultrasonic cutter, employing resonance and vibration to facilitate precise cutting.

If you want to buy, please click here.