Ultrasonic Food(Cake,biscuit)Cutter/Cutting Machine/Blade

$1,500.00 – $1,700.00

6% Off

Ultrasonic food cutter minimize product sticking and deformation, ensuring cleaner cuts and maintaining product aesthetics, especially in layered foods.

They reduce waste by cutting with precision, effectively slicing inclusions like nuts and dried fruits without displacement, even in soft matrices.

Ultrasonic cutting technology enables faster processing speeds, easily integrates into existing production lines, and provides consistent results in food cutting applications.

Designed for low maintenance, ultrasonic cutters reduce downtime by eliminating frequent cleaning needs, especially when cutting sticky products.

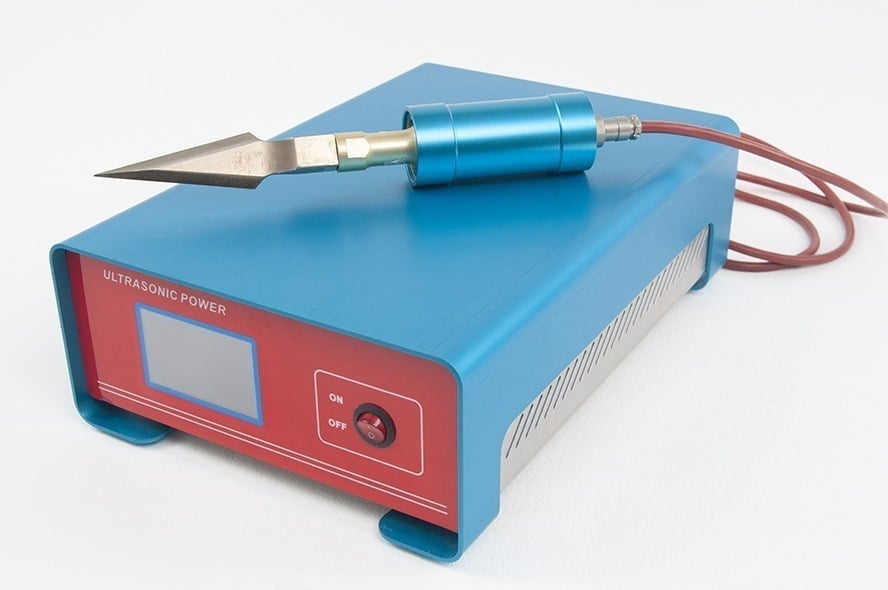

Ultrasonic Cutter Laboratory Industrial Ultrasound Plastic Cutting Knife Machine

$1,599.00

30% Off

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc.

PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials.

FUNCTIONS: Automatic resonance point, automatic frequency sweep tracking in the frequency range of 19-26KHZ. Automatic amplitude compensation, which automatically works at the optimal frequency point and output point according to the fluidity of the sample. Independent on/off pulse with three modes of continuous use, pulse and timed continuous ultrasound.

NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape.Rotary Ultrasonic Cutter Laboratory Industrial Ultrasound Plastic Cutting Knife Machine

$1,799.00

28% Off

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc.

PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials.

FUNCTIONS: Rotary Ultrasonic Cutter is a large amplitude type where the blade vibration amplitude is made larger than conventional models. With a 42 mm diameter cylindrical shape, the model is easy to be mounted on automated machinery, industrial robots and plotters. It is best suited for cutting and punching processing of 3D parts by mounting on industrial robots, in addition to processing of sheets and punching.

NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape.