Occasionally people will confuse vibration welding and ultrasonic welding because both processes use vibratory energy to weld plastic assemblies. However, both processes are very different from each other. Let’s look at the differences between the two processes and how you can use them to your advantage.

Vibrate to weld plastics

Both vibration welding and ultrasonic welding use vibration to create friction and generate heat to weld plastics.

Direction of vibration

The vibration welding process vibrates one component relative to another in a linear side-to-side motion. Take a second to rub your hands together like you are trying to warm up from the cold. You are making the same motion that a vibration welder does with two parts. The friction between the two objects generates the heat used for welding.

Conversely, the ultrasonic welding process vibrates one component perpendicularly to another much like a jackhammer on pavement. This may seem counterintuitive to vibrate in this direction, but ultrasonic welding vibrates incredibly fast which causes molecular friction and generates heat.

Vibration Welding

Ultrasonic welding

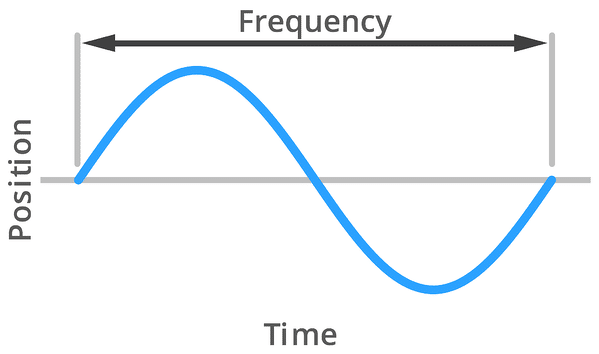

Frequency of vibration

Frequency is the measure of how many vibratory oscillations are completed in one second. The vibration welding process vibrates approximately 120-240 times per second, or 120-240 Hz, depending on the size of the parts being welded. This frequency is well within the human hearing range, so vibration equipment uses sound dampening enclosures to protect machine operators from the deafening fog-horn-like sound.

Ultrasonic welding vibrates at ultrasonic frequencies, which is where the name comes from. So, what are ultrasonic frequencies? They are frequencies above which the human ear can hear, typically 20,000 Hz or 20 kHz. Most ultrasonic processes operate between 20 and 40 kHz. Some operate at 15 kHz which isn’t technically in the ultrasonic range but is still considered ultrasonic welding. 20-40 kHz applications are quieter than vibration but do produce some high-pitched screeching sounds due to lower, resonant frequencies from the plastic parts.

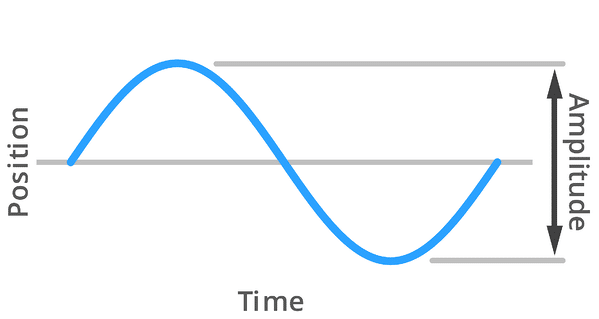

Amplitude of vibration

Amplitude is the distance between the two furthest points of vibratory motion. In vibration welding, the amplitude is typically between 0.4 and 1.8 mm in high-frequency machines and 1.8 and 4.0 mm in low-frequency machines. The lower the amplitude, the higher the frequency.

Ultrasonic welding, by contrast, uses much smaller amplitudes. Many applications use between 25 and 125 microns or 0.025-0.125 mm. Like in vibration welding, the lower the amplitude, the higher the frequency.

Welding time

Vibration welding is a fairly quick process with typical cycle times in the 5-10 s range, but ultrasonic welding is much faster with typical cycle times falling between 1 and 3 s.

Part sizes

Vibration is capable of welding a wide range of assembly sizes. It can be used to weld small assemblies such as automotive armrests and glove boxes, and large assemblies like laundry machine drums and automotive instrument panels.

Ultrasonic is limited to smaller welds. Some components can be downright tiny, like flash drives and in-ear headphones, while the largest components that can be ultrasonically welded are typically no bigger than 6 x 8 in. However, it is common to see multiple ultrasonic tools or stacks being used to weld several small components onto a larger part such as ports and brackets onto an engine manifold.

Best uses

In summary, vibration welding is a great process because it is fast compared to other processes that are capable of welding large assemblies like hot-plate welding and infrared welding. It produces strong, robust welds that can be leak-proof if the application requires it. It is well-suited for applications like:

- Instrument panels

- Intake manifolds

- Glove boxes

- Armrests

- Taillamps

- Power tools

- Surgical instruments

- Filters

- Home appliances

- …and more

Ultrasonic welding is a versatile process that is very fast and excellent for small components. It can also produce leak-proof welds and is useful when welding small components onto larger assemblies. It is best-suited for applications such as:

- Small electronics housings

- Packaging

- Ports and brackets onto larger components such as intake manifolds

- Instrument cluster trim

- Automotive acoustic padding

- …and more