Understanding Homogenization Technology:A Comprehensive Guide

Homogenization technology is an indispensable part of modern industry, playing a crucial role in the processing and manufacturing of a wide range of products. This comprehensive guide delves into the purpose, applications, and nuances of homogenization, offering insights into why this process is vital across various sectors.

The Essence of Homogenization: Particle Size Reduction

At its core, homogenization aims to minimize the size of particles within a sample. Imagine transforming a large boulder into uniform gravel pieces. In homogenization, samples often reach nanometer sizes, aiding in the production of adhesives, resins, paints, and even skincare products by ensuring consistency and functionality.

Critical in Molecular Studies: Cell Lysis

In molecular and cellular biology, homogenization serves an essential function in breaking cell walls or membranes. This process exposes the intracellular materials, facilitating biological research, experimentation, and sample preparation for further studies.

Enhancing Safety: Pathogen Elimination

A significant aspect of homogenization is its ability to destroy pathogens within samples. Various homogenizers, such as mechanical, high-pressure, and ultrasonic types, utilize specific forces that not only process the samples but also can achieve varying levels of sterility. For instance, high-pressure homogenizers are particularly effective in sterilizing food samples, crucial for ensuring safety.

Improving Product Consistency: Stable Emulsions and Dispersions

Homogenization is key to creating stable emulsions and dispersions, essential for products requiring consistency in appearance, taste, texture, and nutritional value. This process enables particles to combine effectively, maintaining stability over extended periods. It’s particularly vital for cosmetics, food, beverages, and pharmaceuticals, ensuring they remain consistent throughout their shelf life.

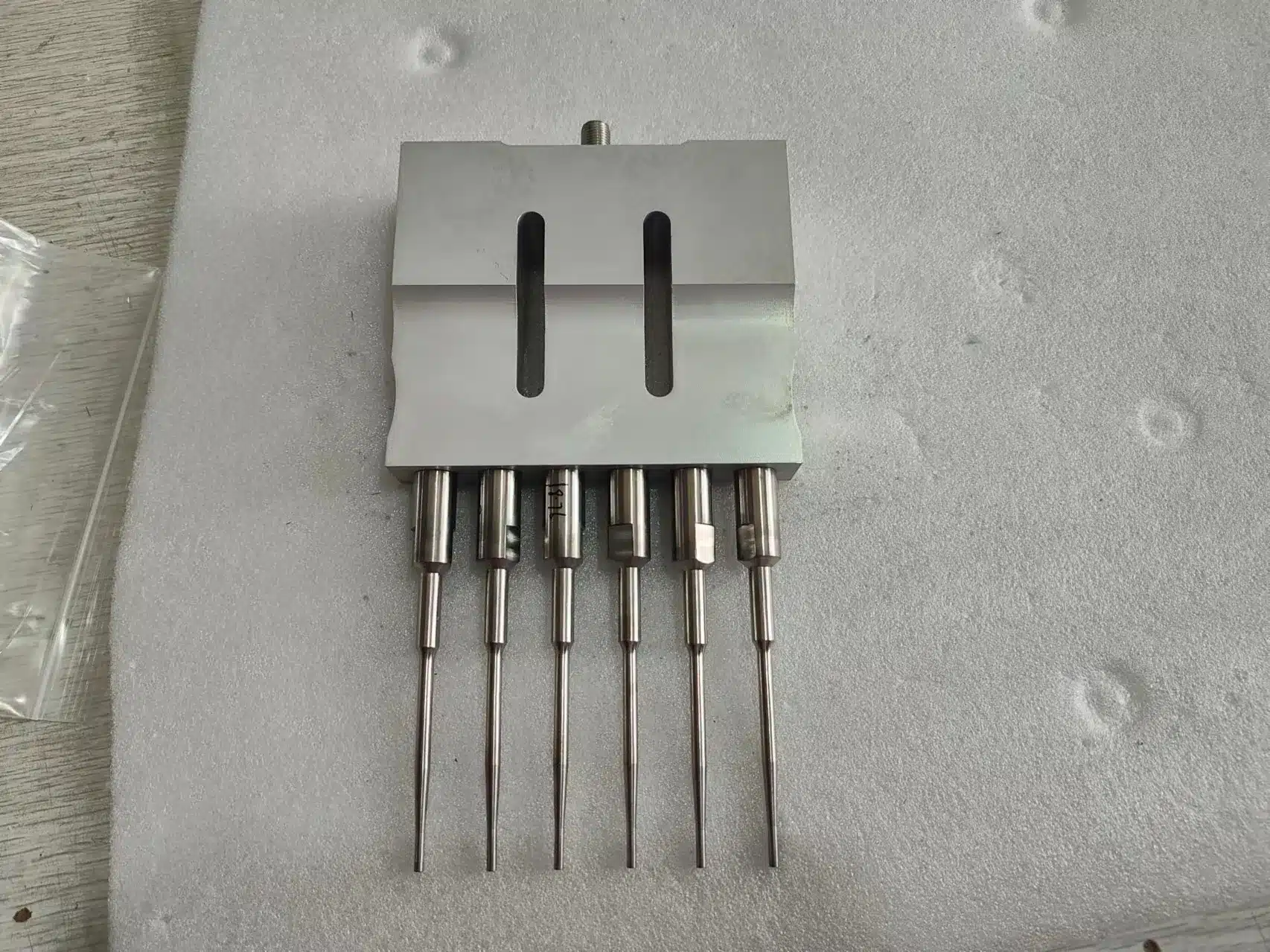

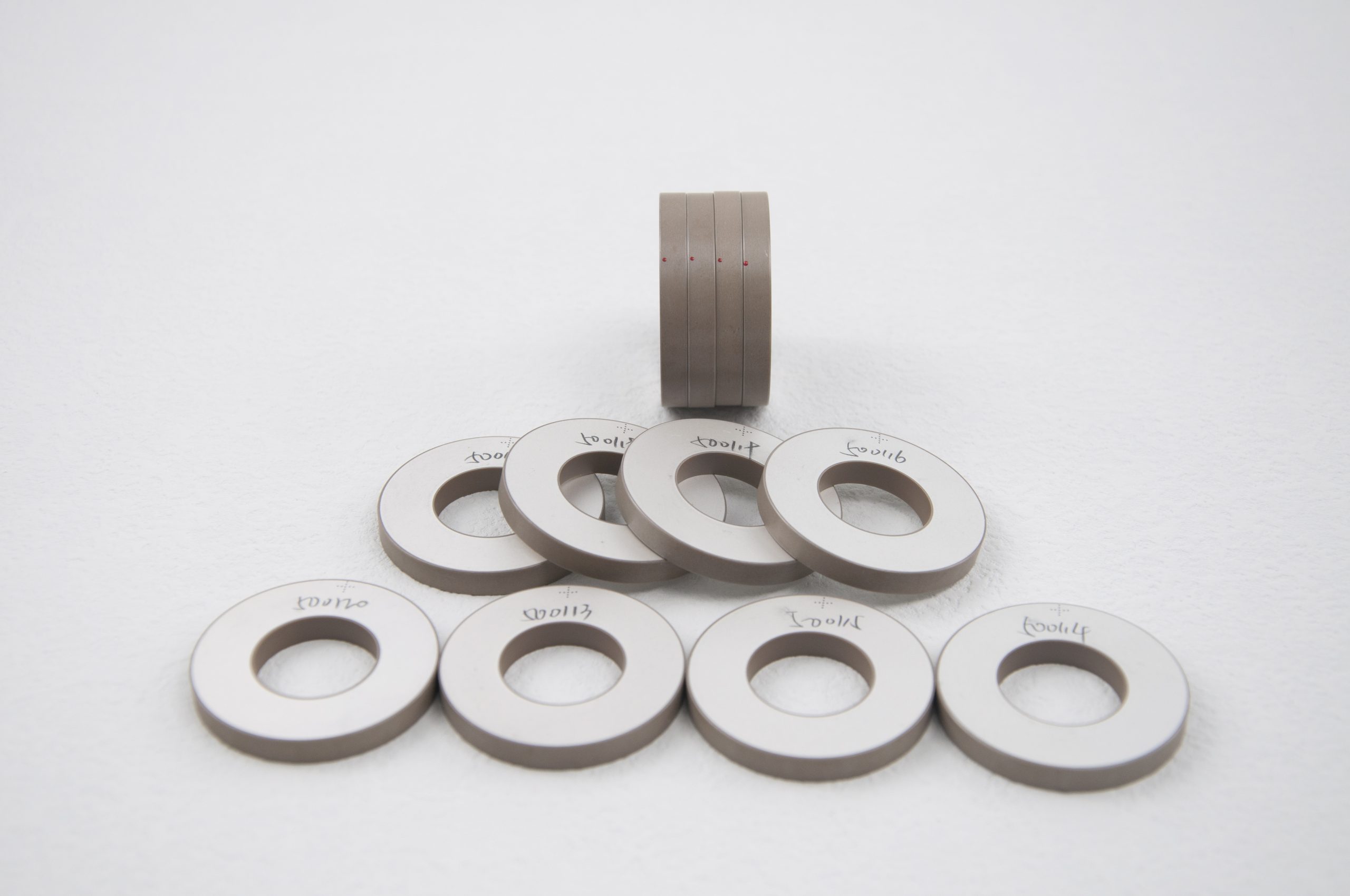

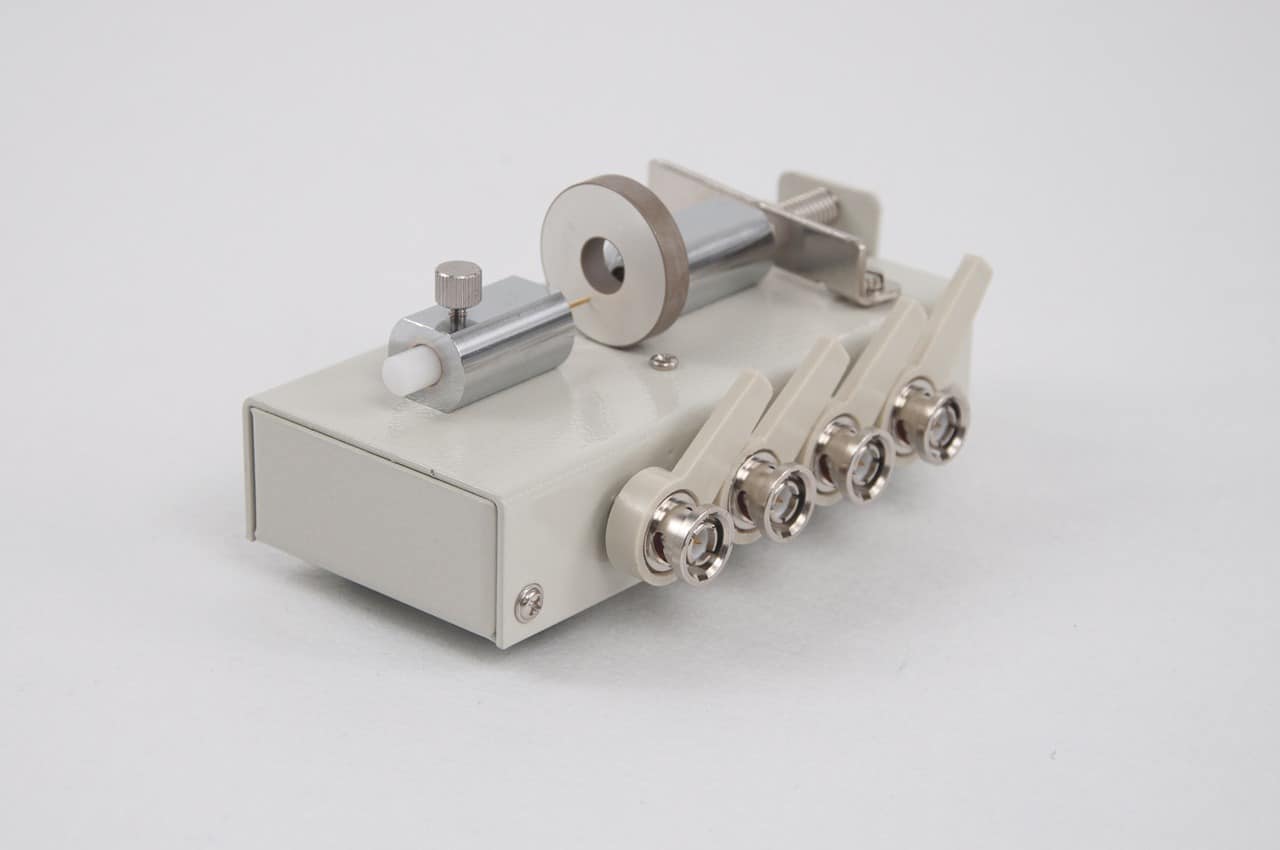

Choosing the Right Equipment: Factors to Consider

Selecting the appropriate homogenizer is crucial. Different applications may require specific types of homogenizers, considering factors like sample sensitivity to heat or the need for sterility. The right equipment ensures efficiency, product quality, and safety.

In conclusion, understanding and utilizing homogenization technology effectively is key to advancement in various industries. From enhancing product quality to ensuring safety and consistency, the role of homogenization cannot be overstated.