Ultrasonic cutting is an innovative technology that utilizes high frequency vibrations to cut through food products cleanly and precisely. This method provides significant benefits over traditional mechanical cutting techniques for many foods. In this article, we will explore how ultrasonic cutting works, its advantages, and some of the foods that benefit most from this advanced slicing method.

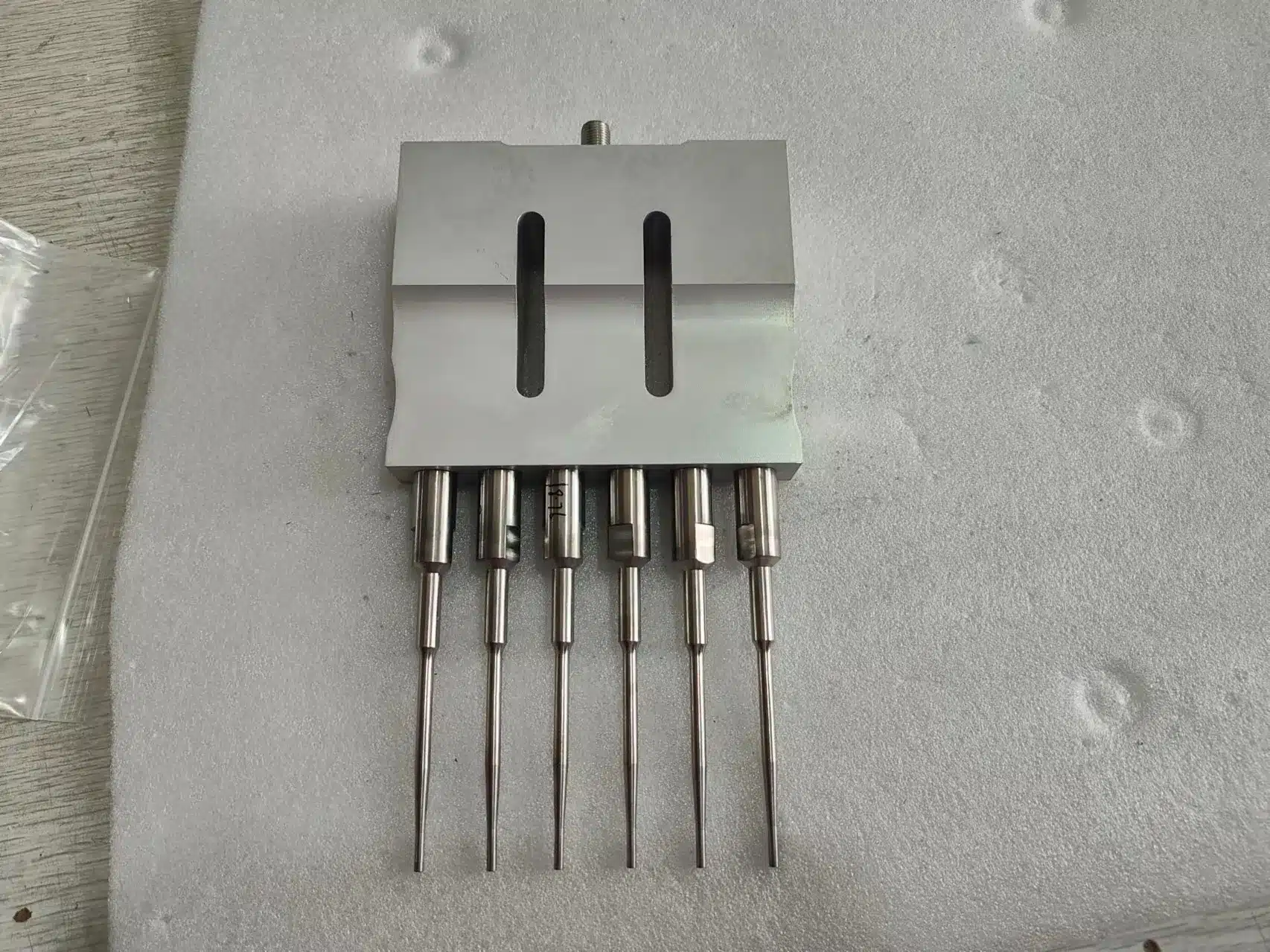

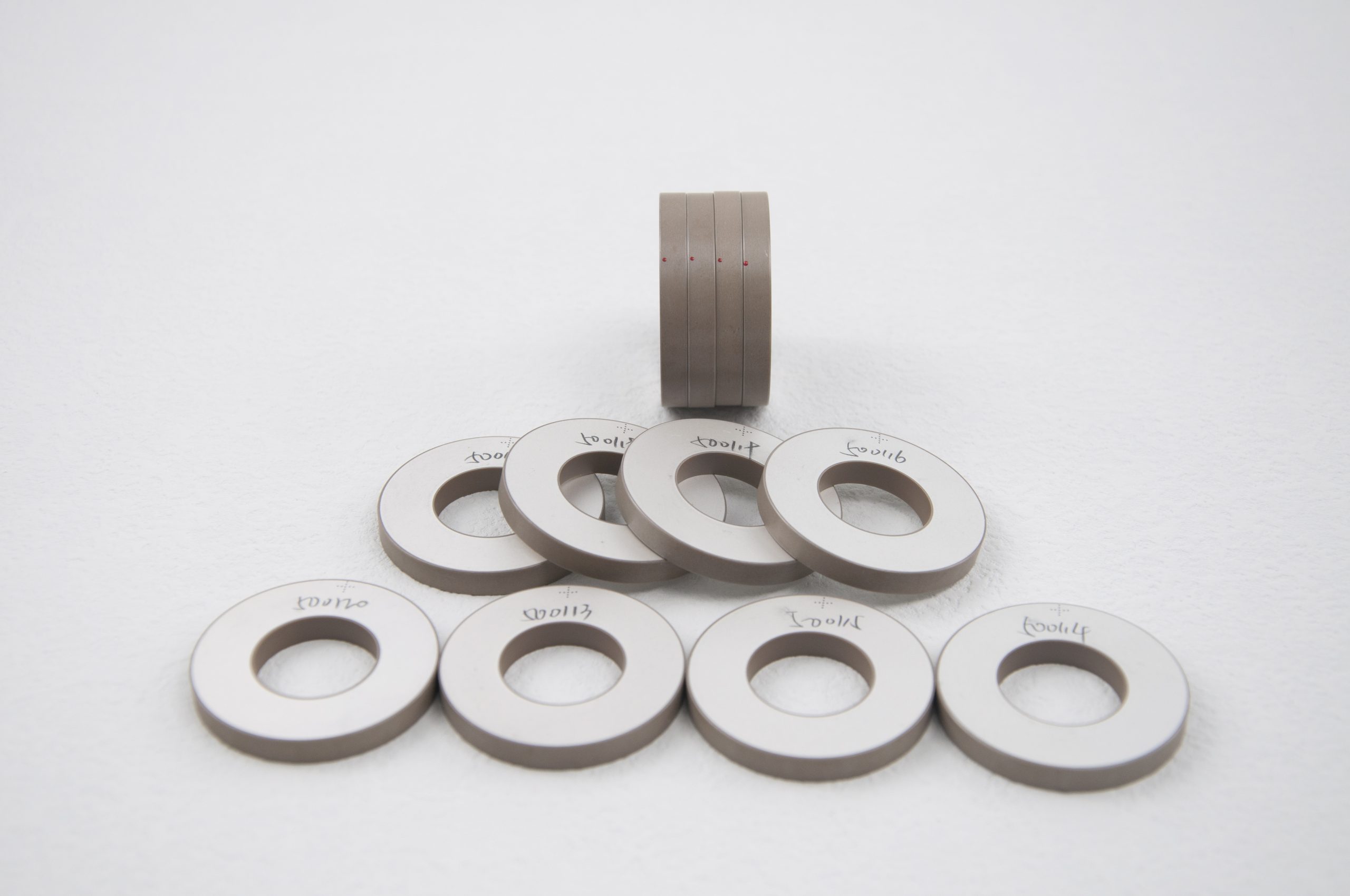

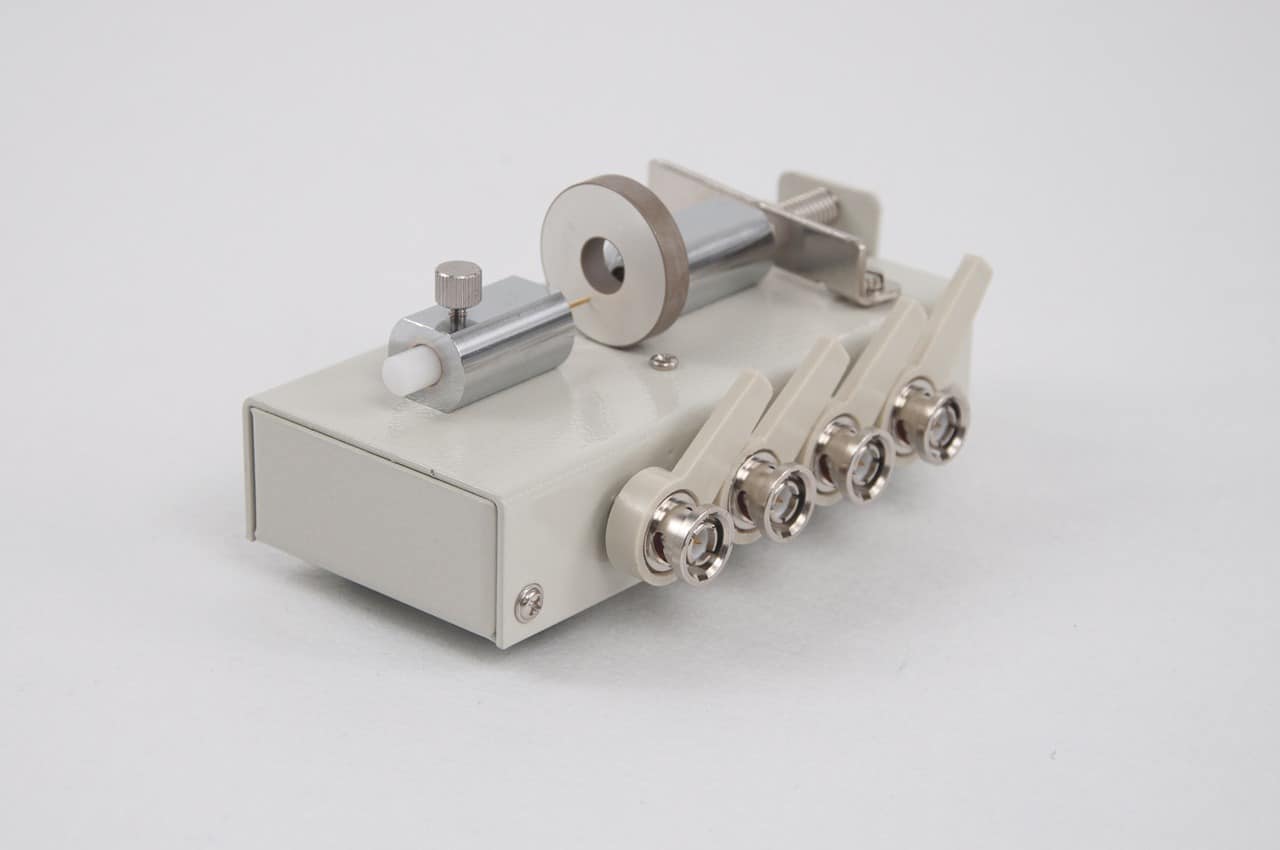

The core components of ultrasonic cutting systems include an ultrasonic generator, converter, booster, cutting tool, and handling equipment. The generator converts electric current into high frequency vibrations that are transmitted through the system to the cutting tool. These vibrations occur at ultrasonic frequencies above human hearing range, typically between 20,000-40,000 oscillations per second.

When ultrasonic frequency vibrations are applied to cutting tools like knives and blades, it creates a low friction cutting surface. This allows the tools to slice through foods with very little resistance. Ultrasonic cutting produces precise, clean slices without squashing soft textures or shattering hard foods. It also significantly reduces friction and release force, preventing issues like sticking.

There are several notable benefits to using ultrasonic cutting technology for food production and preparation:

Precision – The ultrasonic blades can make cleaner, thinner, and more uniform slices than traditional methods. This allows for beautiful presentation and portion control.

Minimal Deformation – Soft, delicate foods like layered cakes, sandwiches, and ripe fruits are precisely sliced with minimal damage or squashing.

Reduced Sticking – Foods like candy bars, cheeses, and frozen meats are less likely to stick to the blades during slicing.

Versatility – Both hard and soft products can be accurately cut in the same production line. Everything from frozen fish to fresh bread can be sliced using the same ultrasonic equipment.

Sanitation – The ultrasonic tools and system components can be easily washed and sterilized to meet food hygiene requirements.

Consistency – Uniform cutting precision and automated handling improves output consistency compared to manual slicing variations.

Ultrasonic cutting also produces less friction and waste than other automated systems like high-speed reciprocal saws. Food manufacturers can use these systems to cut goods into portions, shred ingredients like cheese or cabbage, dice vegetables, and much more. Common foods and products cut using this method include:

- Breads, cakes, and pastries

- Fresh produce like tomatoes and peppers

- Deli meats and cheeses

- Frozen seafood and meat

- Candy, nougat, and snack bars

- Ready-to-eat sandwiches and wraps

With the benefits of reduced sticking, precision cutting, minimal waste, and improved food quality, ultrasonic cutting is an efficient and high-performance solution for many commercial food processing applications. Companies looking to upgrade automated slicing capabilities would be wise to consider implementing this innovative technology.