- PZT8 and PZT4 are the common “hard” piezoceramic materials used in power ultrasonic transducers (e.g., welding, cutting, sonar, etc.).

- PZT8 se percibe como la mejor opción para dispositivos resonantes, principalmente debido a su factor de calidad mecánica Qm más alto. PZT8 también se considera un material "más duro" en comparación con PZT4, ya que tiene una mejor estabilidad en cargas y niveles de conducción más altos.

- PZT4 se utiliza en la transmisión de señales, tiene claras ventajas como una mayor salida (es decir, un d33 más alto), principalmente aplicaciones: sonar, transmisor acústico submarino.

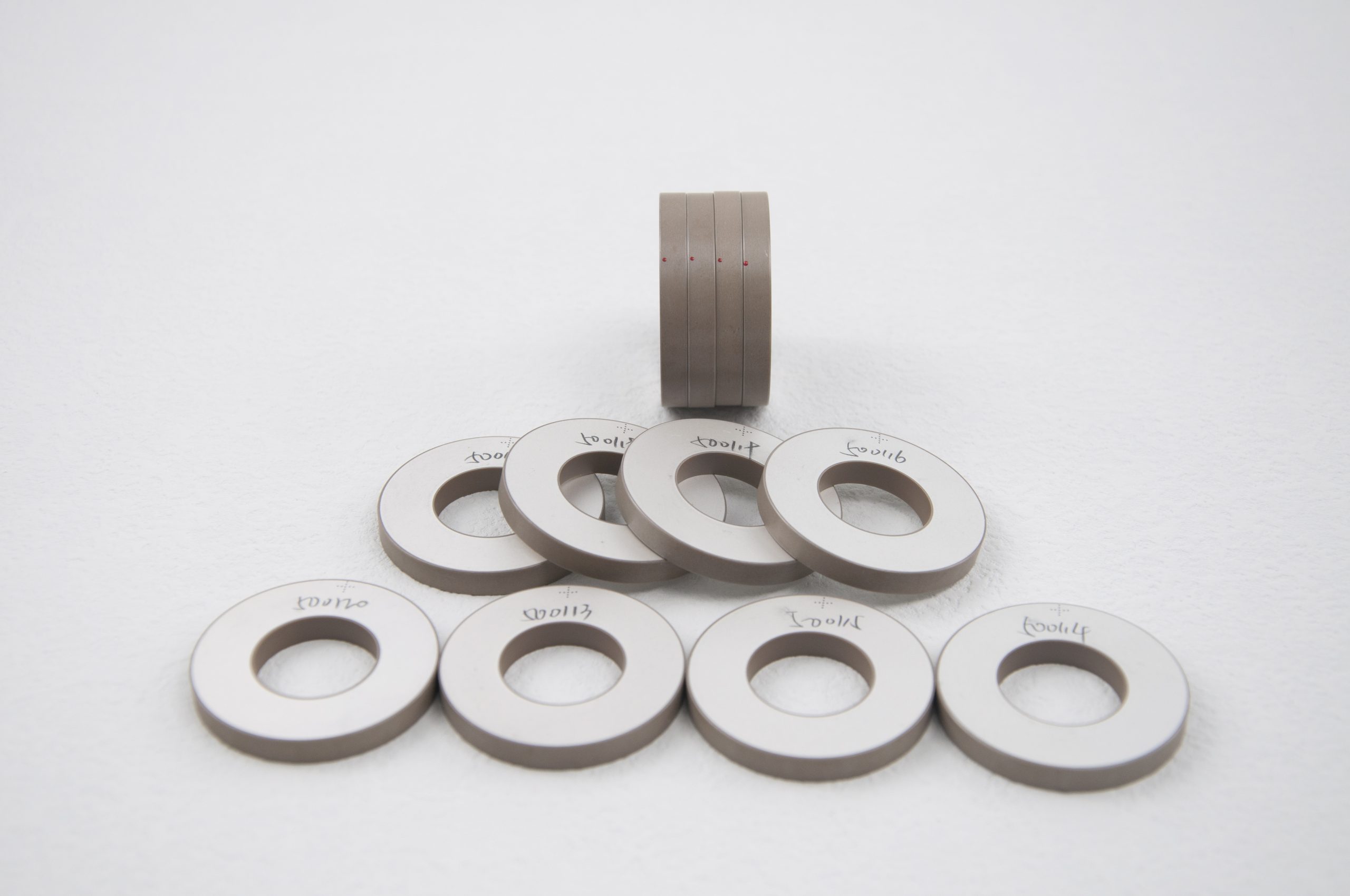

So in a word, the Piezo Ceramic disks and plates for ultrasonic transducers applications:

Piezoceramics for ultrasonic cleaning PZT-4

Standard dimensions and specifications for SPZT-4 piezo ceramic disks – for ultrasonic cleaning applications

Piezoceramics for ultrasonic welding PZT-8

Standard dimensions and specifications for SPZT-8 piezo ceramic disks – for ultrasonic welding applications

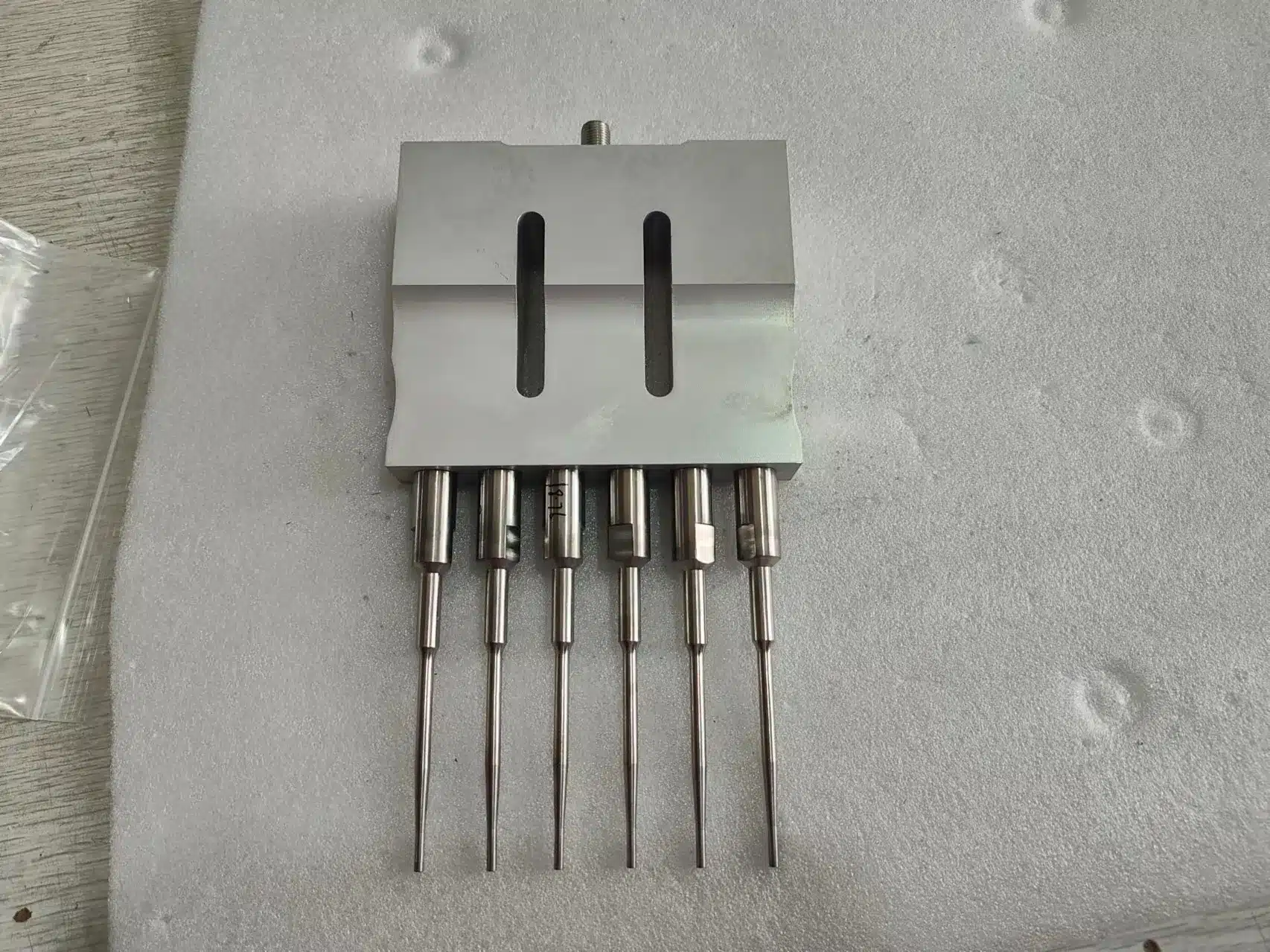

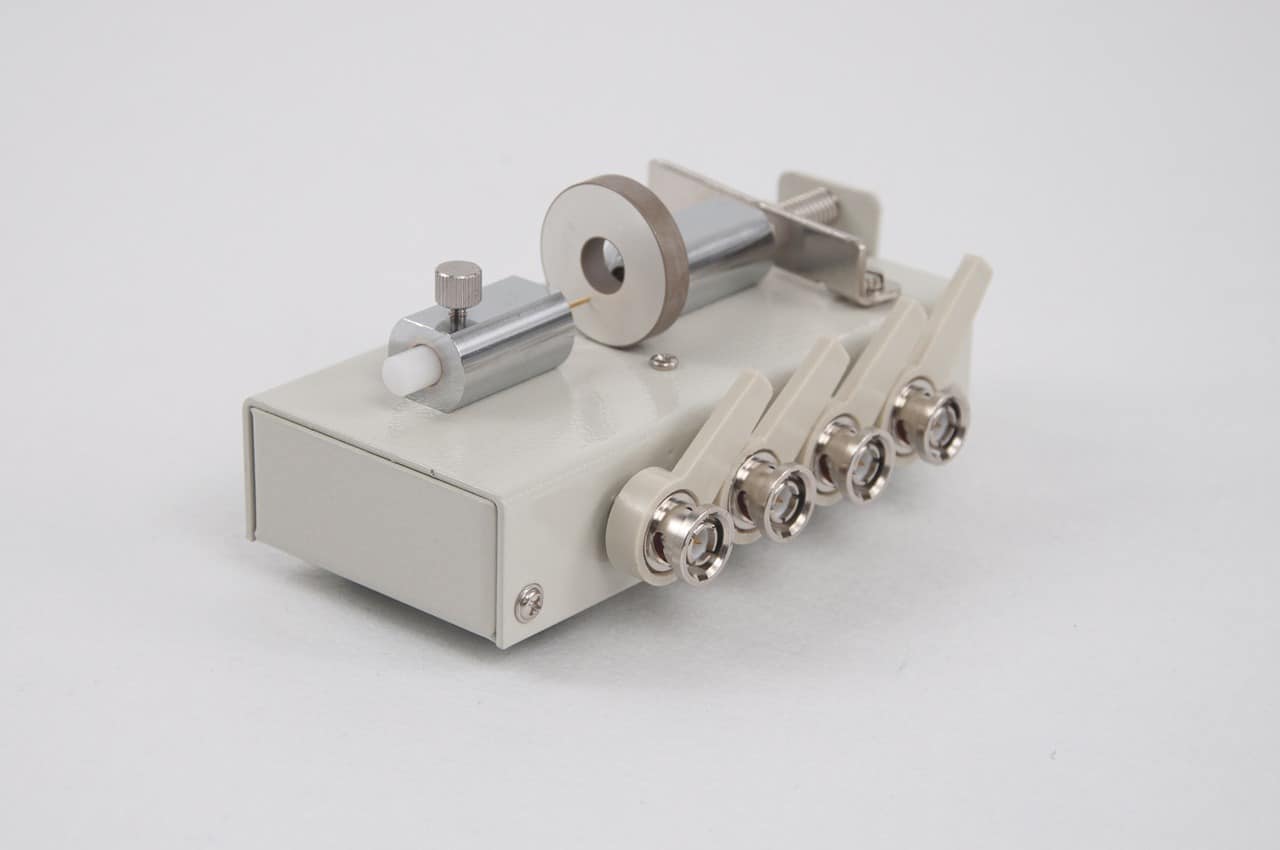

Disk and plate ultrasonic cleaning transducers

Disc and plate transducers are installed at bottom of cleaning tank and operate at frequencies from 35kHz to several MHz. These transducers are ideal for creating a compact and efficient cleaning system, particularly suitable for precision cleaning eg. in semiconductor and optical manufacturing processes.

Poreless Piezo Ceramic Materials

Poreless piezoceramic has much higher specific (ultrasonic) power density, high strength, wide amplitude characteristics, low aging rate, and extremely low porosity in comparison to any other piezoceramics.