1. Structure of semiconductor refrigeration system

In the semiconductor refrigeration system, TEC1-12703 temperature difference electric refrigeration module is used as the cooling plate. According to the characteristics of the lighting system, organic glass with visibility, toughness and high temperature resistance is selected as the refrigerator wall. In order to better solve the heat dissipation problem of the solar LED lighting system, a controller is used to effectively control the semiconductor refrigeration system.

2. The composition and control principle of semiconductor refrigeration controller

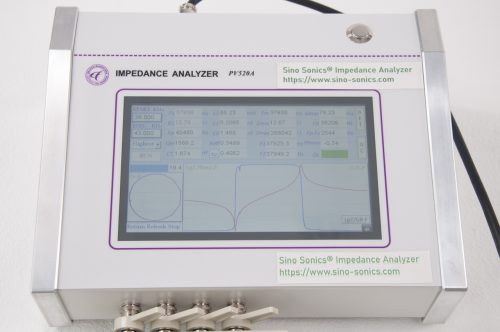

According to the theory of semiconductor refrigeration, applying a DC voltage across the TEC (semiconductor refrigeration system) will generate a DC current, which will cause one end of the TEC to generate heat and the other to cool. We call the hot end the “hot end” and the cold end the “cold end”. Reverse the polarity of the voltage across the TEC, the current will flow in the opposite direction, and the “hot end” and “cold end” will be interchanged. As a cold and heat source in semiconductor refrigeration applications, TEC has reversible operation, which can be used for both cooling and heating. In order to solve the actual situation of the heat dissipation problem of solar LED lighting system, we choose the highly integrated high-performance single-chip microcomputer ADUC824 as the control core, and complete the control of the semiconductor refrigerator through software programming. ADUC824 is a high-performance single-chip microcomputer with 8051 core introduced by AD. It integrates two (21-bit + 16-bit) A / D, 12-bit D / A, FLASH, WDT, μP monitoring, temperature sensor, SPI and I2C bus interface, etc. Rich resources are integrated into one. ADUC824 is small in size, low in power, and has online programming and debugging functions, without the need to develop a device. ADUC824 is used as the core of the semiconductor refrigeration controller, which improves the reliability of the design and greatly simplifies the design of the circuit. The semiconductor refrigeration power drive uses H-type (full bridge) circuit, which can complete the bi-directional current drive of the load under the condition of single power supply, and complete the operation of TEC refrigeration to achieve the control of the target. The principle block diagram of semiconductor refrigeration control based on ADUC824 is shown in Figure 2 [1].

3.Design Model of Semiconductor Refrigeration System

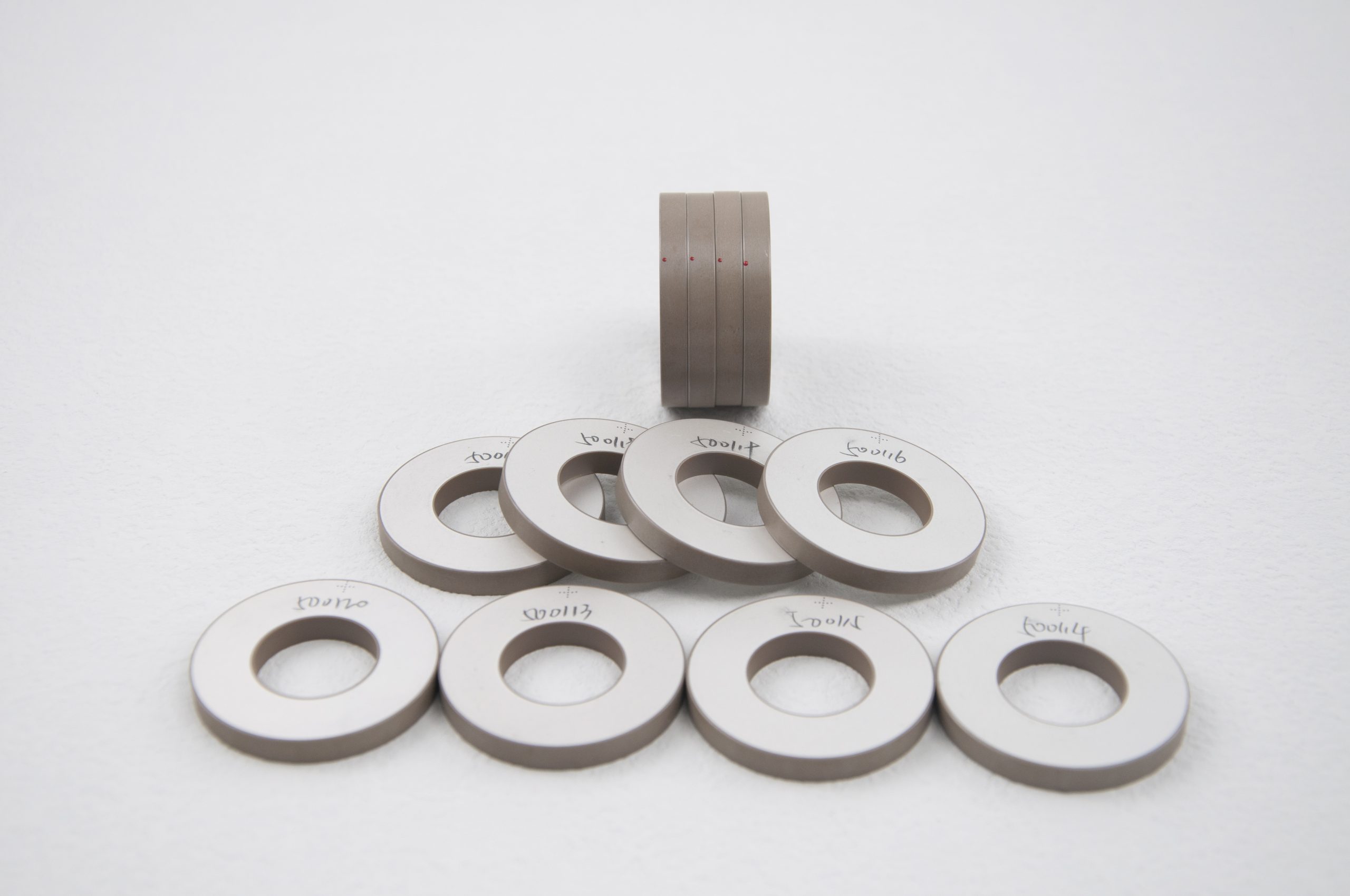

From the previous analysis, it can be known that by using direct current through the PN junction, heat can be transferred from high-temperature objects to low-temperature objects. Changing the direction of current flow can easily realize the conversion of cooling and heating. With semiconductor refrigeration, there is no need to consider the environmental pollution caused by refrigerant leakage, and the entire system has no welded pipes. FIG. 3 is a model structural diagram of a semiconductor refrigeration system. It is composed of many N-type and P-type semiconductor particles aligned with each other, and the NPs are connected by ordinary conductors to form a complete circuit, usually copper, aluminum or other metal conductors, and finally two piezoelectric ceramic plates are used. Clip it up. After the DC power is turned on, the electrons start from the negative electrode (-), first pass through the P-type semiconductor, absorb the heat here, and then release the heat to the N-type semiconductor. Every time an NP module passes, the heat is sent from one side to the other. On the other side, a temperature difference is created, which creates a hot and cold end.