Lead Zirconate Titanate (PZT)’s attributes of producing an electrical charge when mechanically compressed or vibrating when an electrical charge is applied, make it very conducive for passive sensing, active transmitting and mechanical displacement applications.

We utilise two predominant types of piezoelectric materials, each providing a set of unique properties suitable for a range of applications. Two types of piezoelectric ceramics include High Power [Hard” variant and high Sensitivity [Soft” variant

High Power [Hard” Piezoelectric Materials are ceramics able to withstand high levels of electrical and mechanical stress and are particularly suited to high voltage and power applications.

High Sensitivity [Soft” Piezoelectric Materials are particularly useful for sensing applications due to its high sensitivity and permittivity. As such these piezoelectric ceramics are frequently used in low power applications as transducers, receivers and generators.

PZT is a machineable ceramic and can be precision dimensioned into tubes, rings, discs, plates, and hemispheres. The PZT material is also versatile from a forming aspect as it can be net shaped by pressing, extruding and casting into these same shapes as well as complex components including, co-fired bimorphs and multilayer actuators. Sizes range from microns to centimetres. Electrode choices are extensive including fired silver, electroless nickel, sputtered or vacuum deposited Nickel-Chrome, Gold, Tin, Aluminium and Vanadium.

Typical PZT characteristics include:

Wide range of frequencies in transmit and receive (sub-audible, audible, ultrasonic)

High output, low drive material

High frequency, fast response time

High sensitivity for active or passive use

Ability to use with low voltage or high voltage drive circuits

Good mechanical and acoustic coupling

Wide variety of shapes and sizes that can be customized to meet specific requirements and applications

Wide variety of compositions that can be selected to meet specific requirements and applications

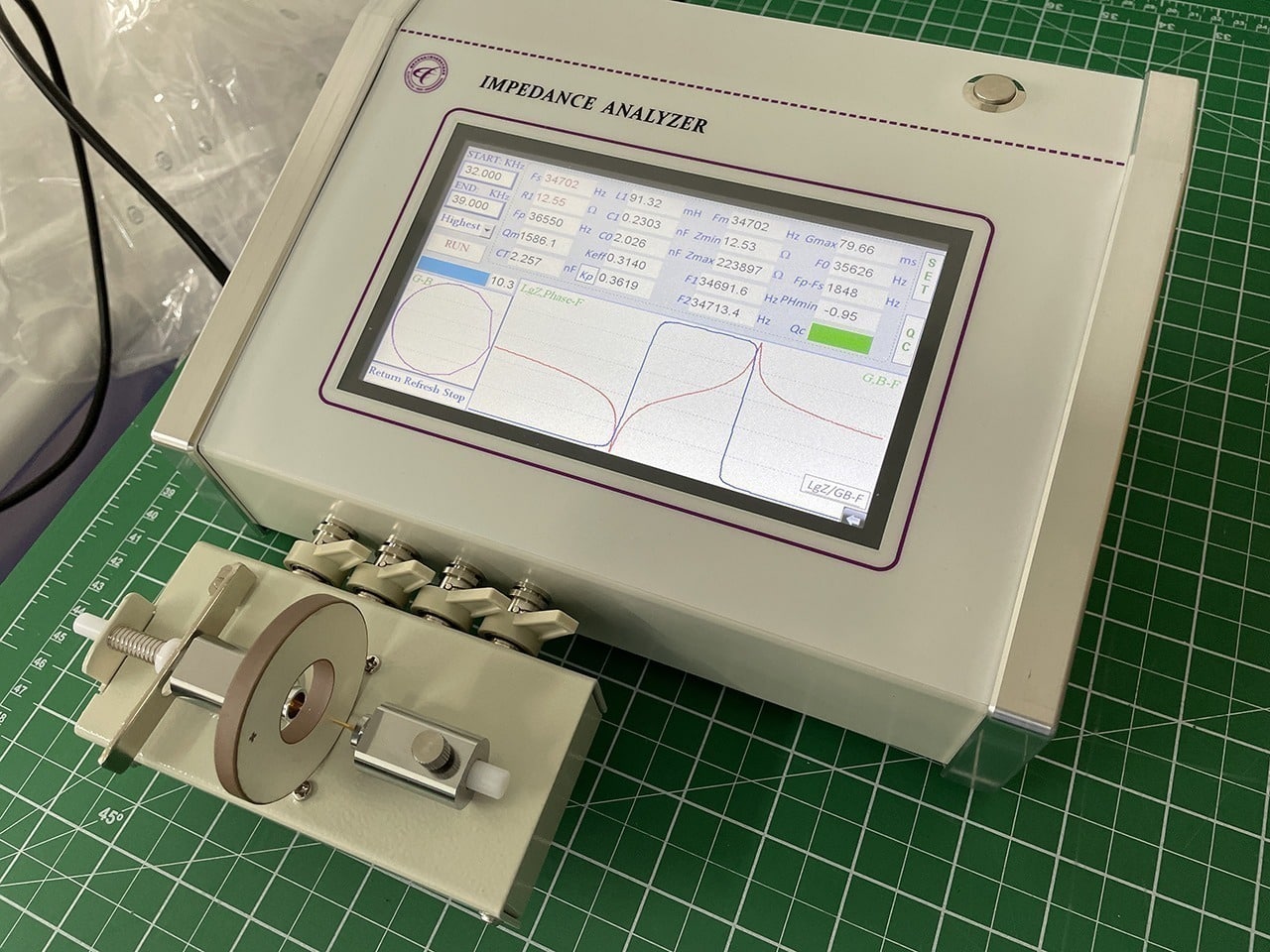

Quality of each PZT component is ensured by a rigorous testing regimen. Characteristics such as frequency, capacitance, dissipation, coupling, d33 and mechanical properties are measured and verified against our / customer provided specifications.

Typical PZT applications include:

* Undersea exploration (sonar, beacons, imaging, current meters)

* Aerospace (gyroscopes, accelerometers, level sensing)

* Medical products (Doppler blood flow, oncology therapeutics (high intensity focused ultrasound), imaging, level sensing, intra-operative tools for ophthalmology (phacoemulsification), dental descaling, general surgery, tissue ablation, medication delivery, hearing enhancement, bubble detection)

* Consumer products (ultrasonic toothbrushes, jewellery cleaners, contact lens cleaners, computer hard drives, touch screen displays, integrated, ultra-thin speakers and cosmetic enhancement)

* Industrial and Commercial (flow and level sensors, ultrasonic cleaning, ultrasonic welding, intrusion alarms, fabric needle positioning, solder dispensing, machine vibration monitoring, bubble detection, sonochemistry for improved chemical mixing)

* Telecommunications (optical switching of telecom lines, buzzers and alarms, Haptics feedback, mobile phone cameras)

* Automotive (power seat controls, reversing/collision avoidance sensors, anti-knock sensors)

* Scientific research (nano positioning stages and analytical tools, scanning probe microscopy, advanced acoustics)

* Oil Exploration (flow and level sensors, down hole drill tool monitoring)