Why ultrasonic cleaners are a green option for industrial cleaning

These days, every industry talks about how they can become more environmentally friendly. But going green isn’t just a buzzword. Implementing green practices into businesses such as industrial or precision cleaning is good for your workers, for your company image, and for the water, soil, and air that the next generation will inherit. These are all great motivators, but what is often not taken into account is that going green can also improve productivity and lower overhead. In addition to helping make a better world, it just makes good business sense.

Solvent-based cleaning is going the way of the dinosaurs

For decades, harsh chemical solvents have been the traditional way to clean tough industrial grime. However, the Montreal Protocol of 1987 began the trend of either outlawing the most harmful solvents outright or limiting their use, due to toxicity to workers and the environment. These days, solvents are sometimes applied via spray cans to limit their application. As they are applied directly to the part being cleaned, however, much of the spray atomizes into the air or drops to the ground. While slightly better than older methods, this still creates an airborne hazard for workers and pollutes the environment. What if there were a better, less costly, and greener solution? Fortunately, there is: ultrasonic cleaning.

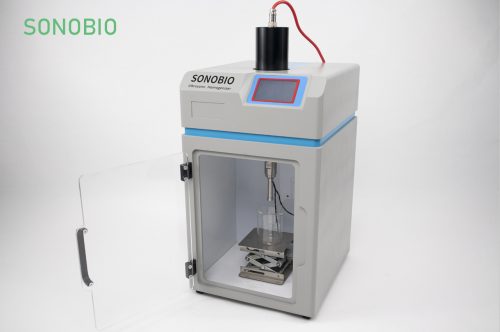

Ultrasonic Cleaning: The Environmentally-Friendly Way to Clean

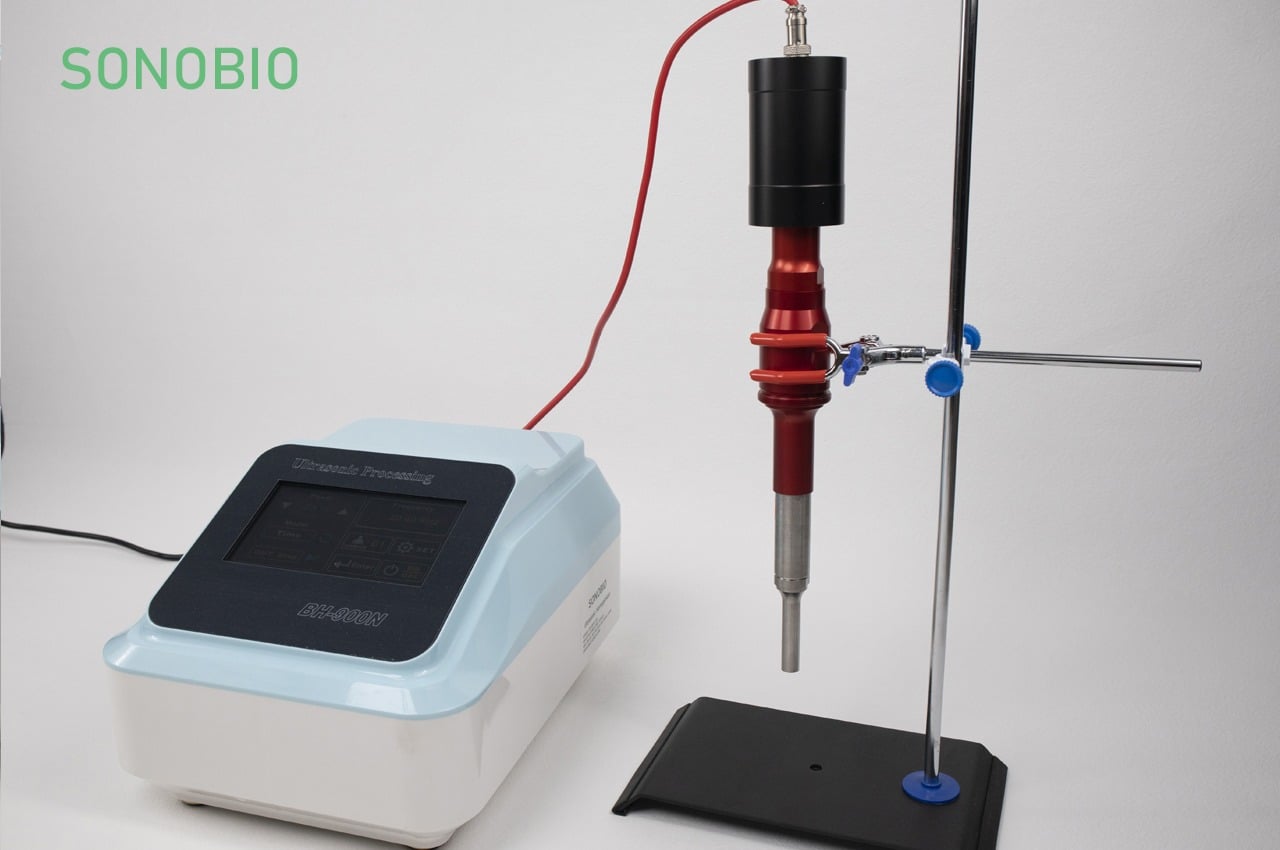

The detergents used in ultrasonic cleaning systems are generally nontoxic, biodegradable, and meet all state and federal Environmental Protection Agency (EPA) guidelines. Ultrasonic cleaners typically do not use harmful chemical solvents, depending instead on a combination of ultrasonic power, plus water and detergents similar to those we find at home.

Of course, discarded water-based detergents must still be treated, since usually the industrial parts being cleaned will inject hazardous oils and chemicals into the wastewater. However, when it comes to treating wastewater from ultrasonic cleaning, companies have many more options than they would with solvents. For example, wastewater recycling can be accomplished through flocculation treatment processes that extract the harmful waste while retaining water to be returned to the environment. Water can be passively evaporated or boiled off, leaving only sludge.

One common objection to using water-based detergents is that they aren’t inherently as powerful as solvents for many types of cleaning. Though modern detergent formulas have become quite specialized and powerful, additional help is still usually needed. This is where the power of ultrasonic cleaning comes in.

Ultrasonic Cleaning Plus Detergents – a Powerful Combo

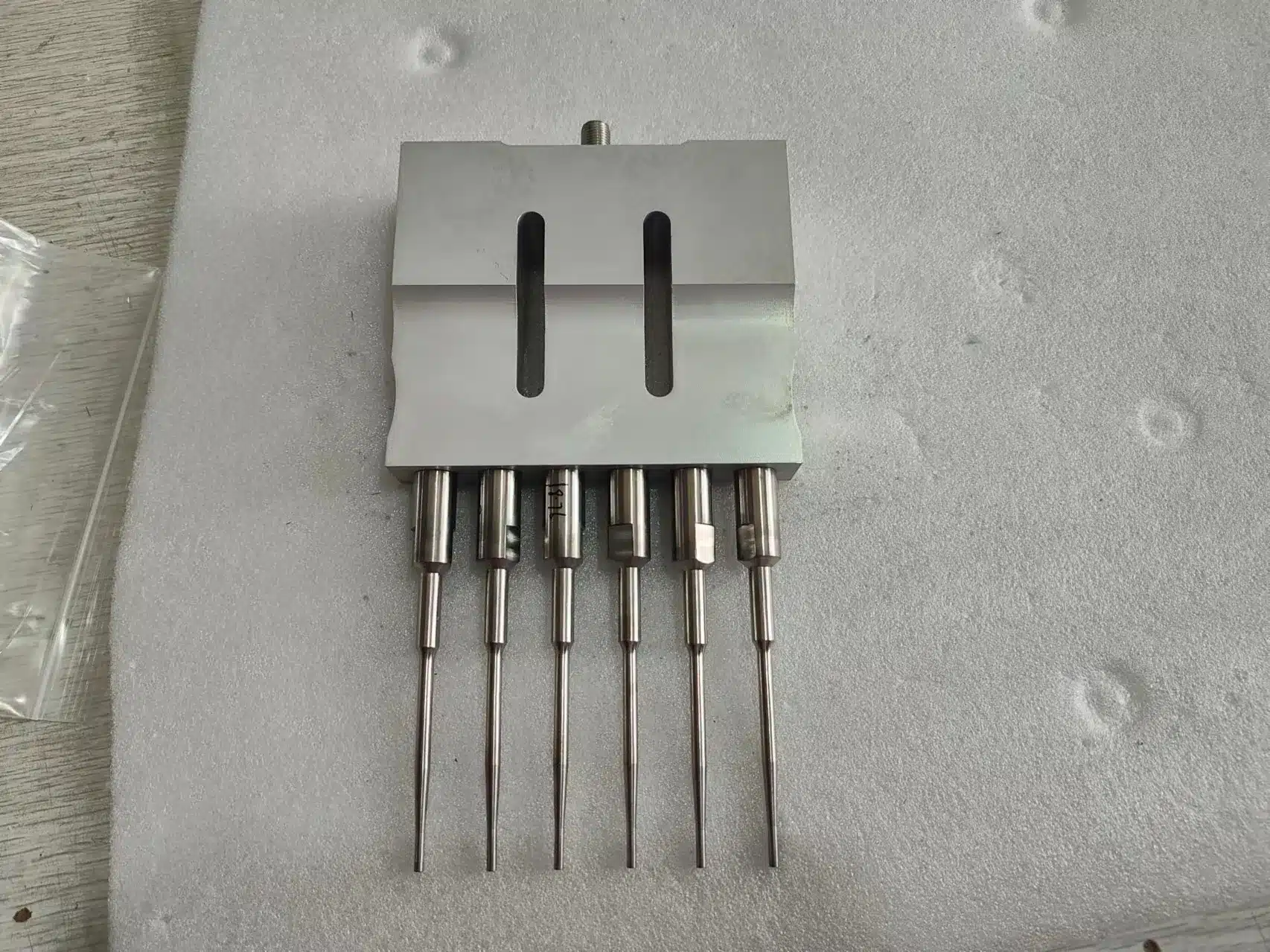

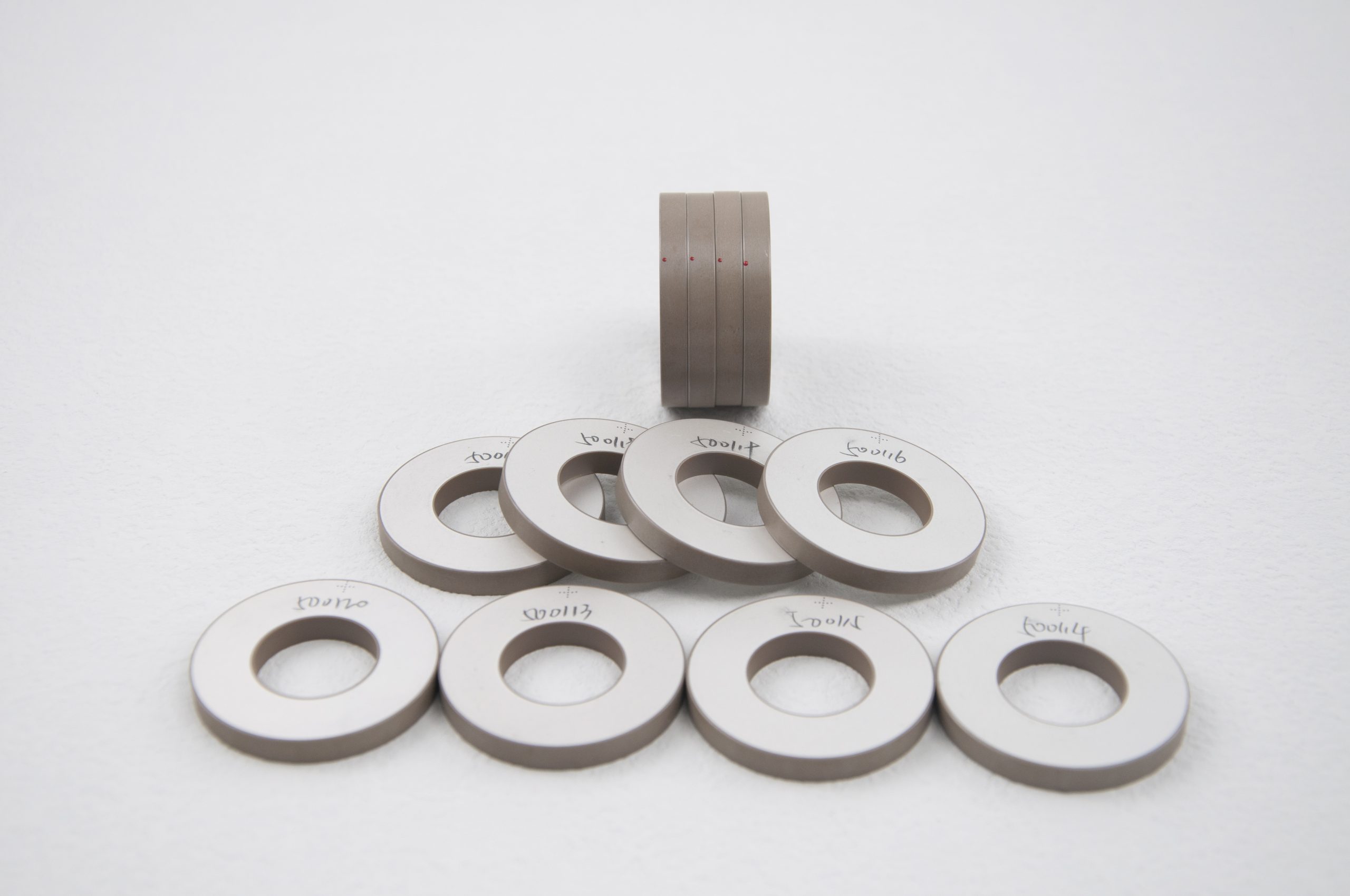

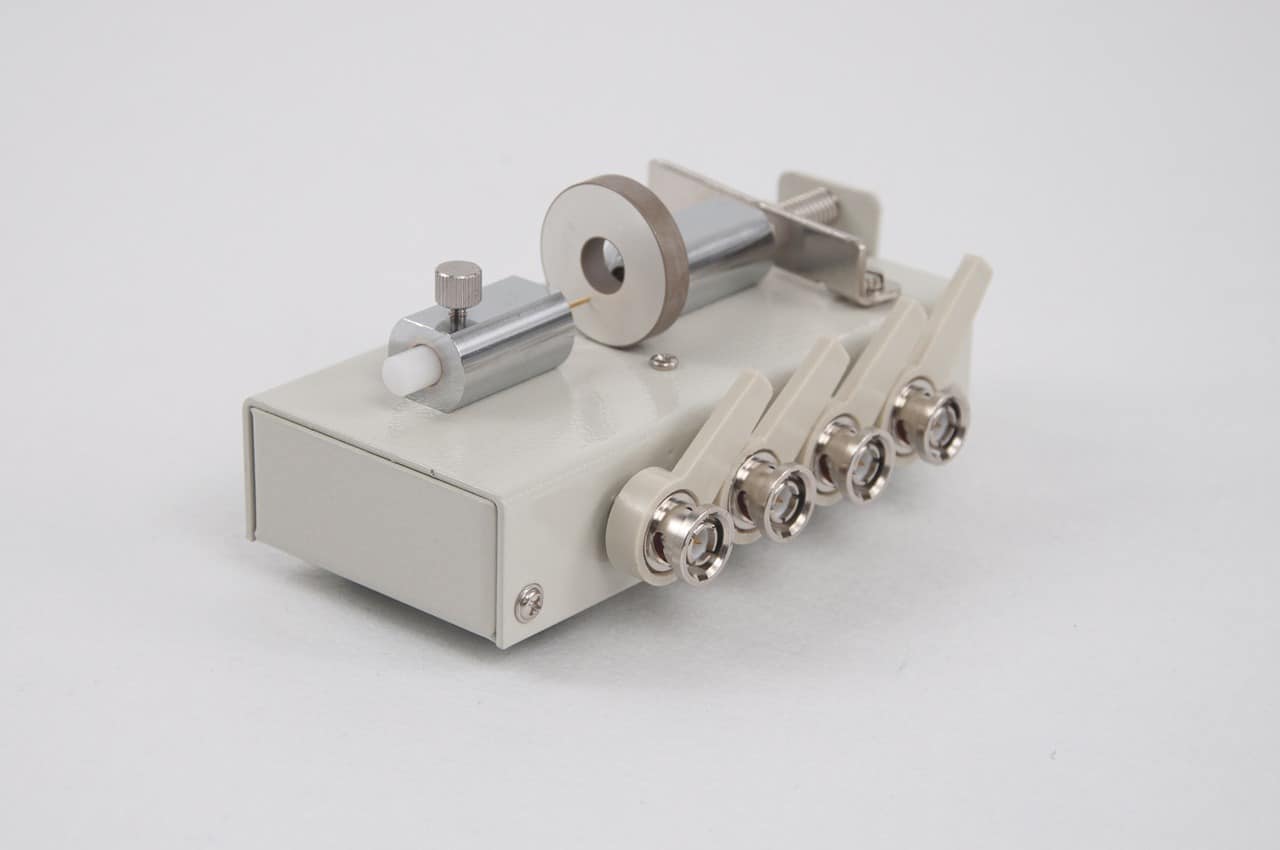

Water-based soaps need some type of mechanical help to overcome their lack of inherent solvency. When an ultrasonic cleaner is turned on, and the ultrasonic sound waves start moving through the liquid, they create millions of microscopic cavitating bubbles, which collapse and produce powerful jets of force against the object being cleaned. One huge plus: for items large or small requiring precision cleaning in threaded areas or inside tubes or blind holes, ultrasound is far superior to any type of solvent.