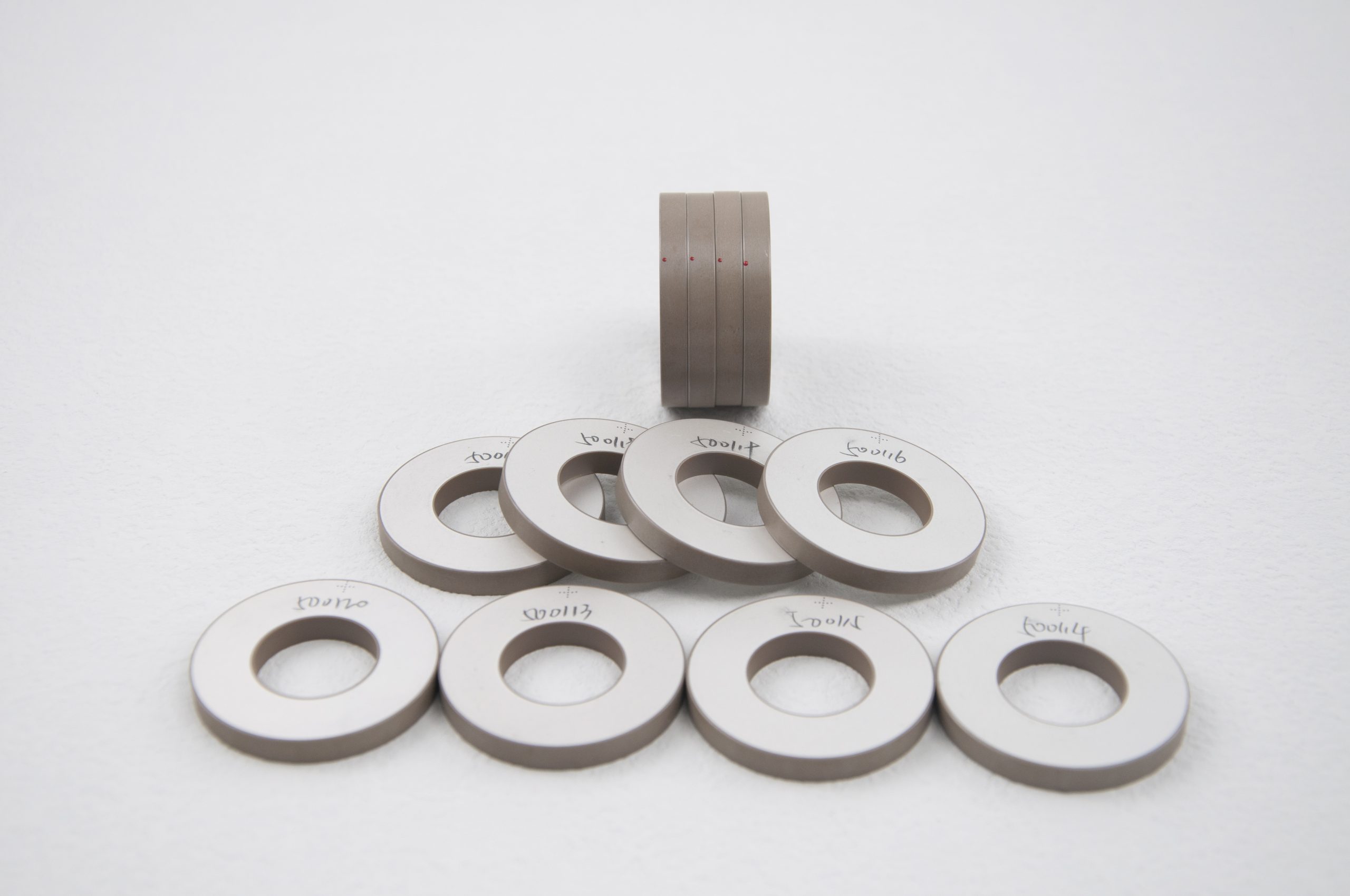

A piezoelectric ceramic piece is an electronic sounding element. A piezoelectric ceramic dielectric material is placed between two copper circular electrodes. When an AC audio signal is connected to the two electrodes, the piezoelectric piece will When a vibration occurs, a corresponding sound comes. Because of its simple structure and low cost, piezoelectric ceramics are widely used in electronic appliances such as toys, sounding electronic watches, electronic instruments, electronic clocks, timers and so on. Traditional piezoelectric ceramics have a stronger piezoelectric effect than other types of piezoelectric materials, and have been widely used. However, as a large application and high-energy conversion material, the piezoelectric effect of traditional piezoelectric ceramics still cannot meet the requirements. So in recent years, people have done a lot of work in order to research new piezoelectric materials with more excellent piezoelectricity, and have now discovered and developed PbPbTiO3 single crystals. This type of single crystal has a maximum d33 of 2600pc / N and a k33 of 0.95. Its strain is> 1.7%, which is almost an order of magnitude higher than that of piezoelectric ceramics.

As an emerging electro-acoustic device, the development of piezoelectric ceramic speakers has undergone a process of twists and turns, but because of its excellent mid-to-high frequency sound, thinner profile structure, and lower power consumption, it has been used in handheld electronic consumer products To have a role to play. Today, as a raw material for dynamic speakers, a rare earth, the overall price increase due to the country’s resource control policy, and the increasingly thinning requirements of handheld consumer electronics products, the demand for piezoelectric ceramic speakers will become more and more common, Some of the friends may not fully understand the working principle of the unique vocalization characteristics, resulting in cognitive bias and design errors.

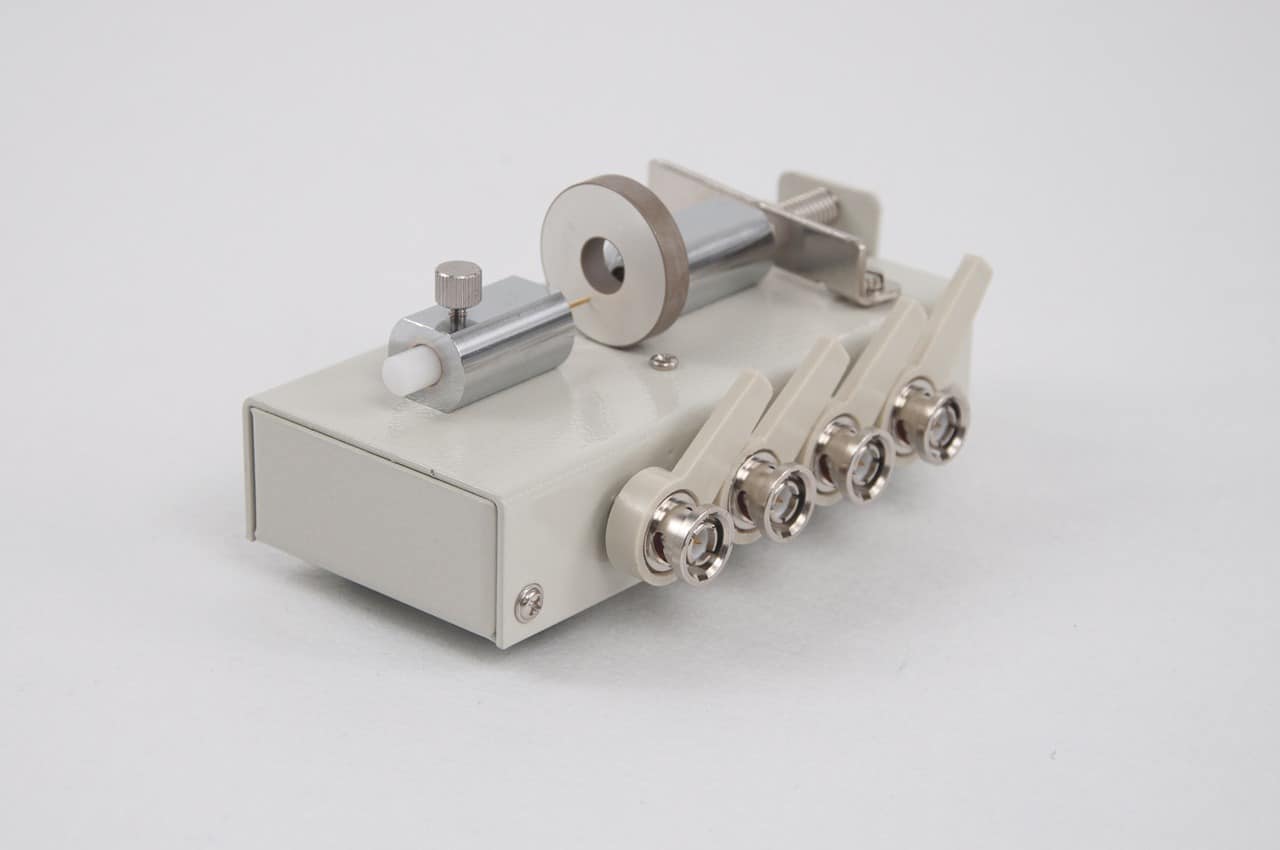

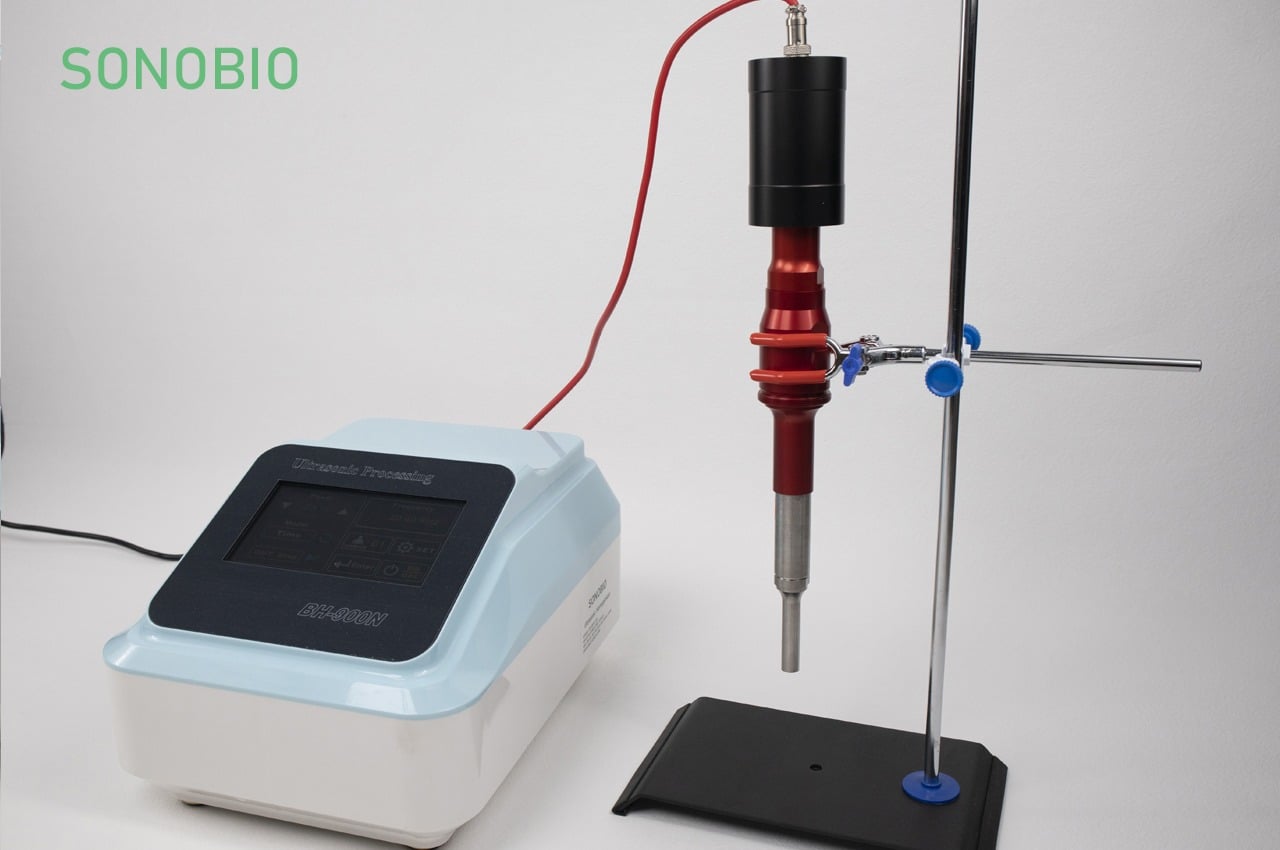

Electrical ceramic transformers use the positive and negative piezoelectric effects of piezoelectric ceramic materials and excite voltages at their resonant frequencies. Therefore, piezoelectric ceramic materials are required to have high electromechanical coupling coefficients and high mechanical quality factors; at the same time, dielectric materials are required. The loss tgδ should be very low to avoid lossy heating during operation. In order to further increase the boost ratio, a piezoelectric ceramic material with higher vibration speed should be developed. In addition, in order to make small power miniature transformers, piezoelectric film transformers should be developed. Piezoelectric ceramics, also called buzzers, are electronic sounding elements. It uses the working principle of piezoelectric ceramics. A piezoelectric ceramic dielectric material is placed between two copper circular electrodes. When an AC audio signal is connected to the two electrodes, the piezoelectric chip will When a vibration occurs, a corresponding sound comes. Because of its simple structure and low cost, piezoelectric ceramics are widely used in electronic appliances such as toys, sounding electronic watches, electronic instruments, electronic clocks, timers, and ultrasonic motors.

Looking back at the development of China’s piezoelectric ceramics industry, only 20 years ago, only Shandong University, Tsinghua University, South China Institute of Technology, Tianjin University, Sichuan University, Shanghai University of Science and Technology have majors in piezoelectric materials and applications, Shanghai Silicate Research The Institute, the 7th Research Institute and the 26th Research Institute of CLP Technology Group have built piezoelectric ceramic materials and application research laboratories. The only manufacturer is Shandong Zibo Radio Ceramics Factory. Most of the major projects are related to military products. The products related to civilian use are only the mass-produced piezoelectric ceramic buzzers and igniters, a small number of multi-chip ceramic filters, mechanical filters used for post and telecommunications, piezoelectric ceramic transducers for underwater acoustics and ultrasound, and so on.