Integrated ultrasonic cutter machines are becoming a key player in industrial cutting technology due to their precision and efficiency. This article explores the components and operational mechanics of these advanced machines.

Ultrasonic Cutter Machine Components

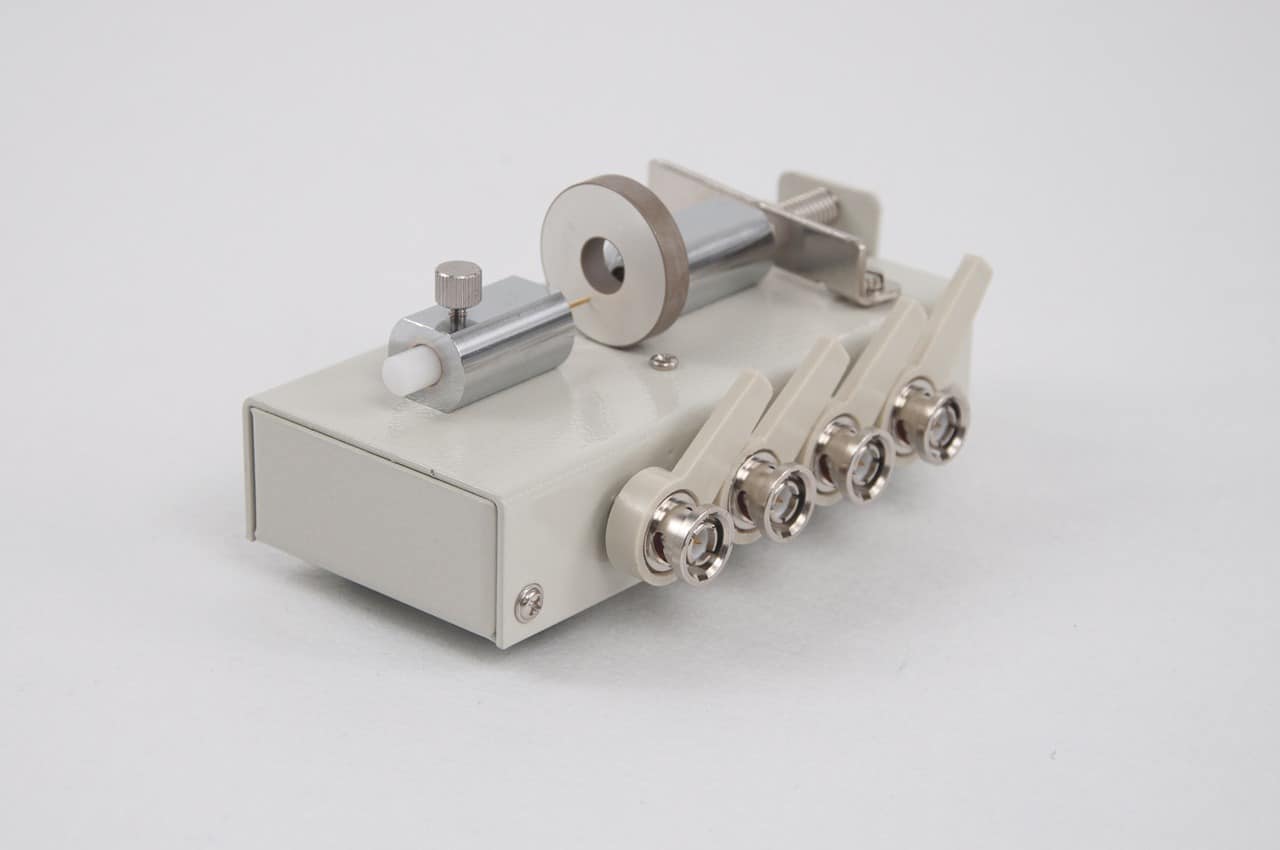

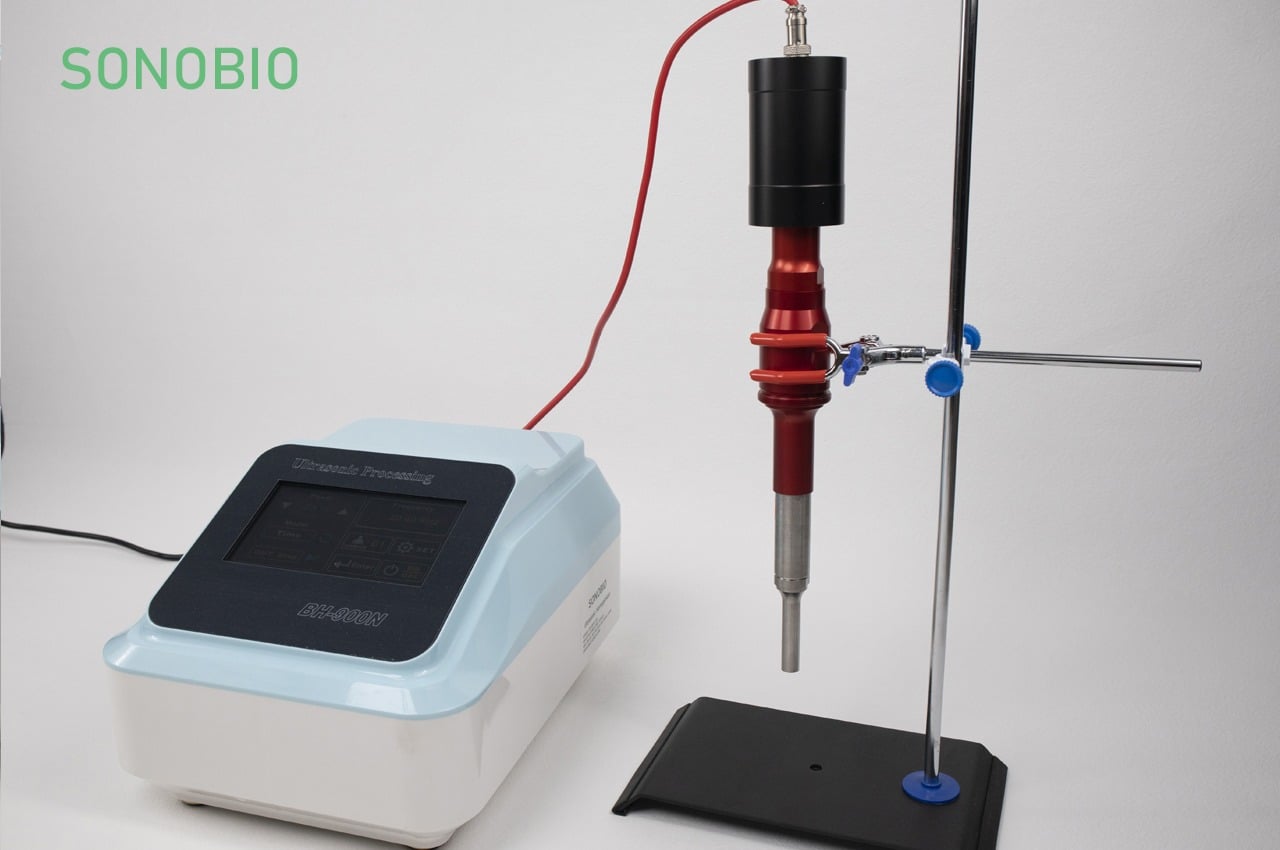

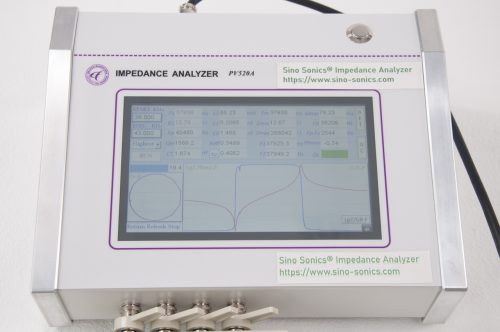

The heart of the ultrasonic cutter machine is its ultrasonic generator. This essential component produces the high-frequency electrical energy needed for cutting. The transducer, connected to the generator, turns this electrical energy into mechanical vibrations, crucial for the cutting process.

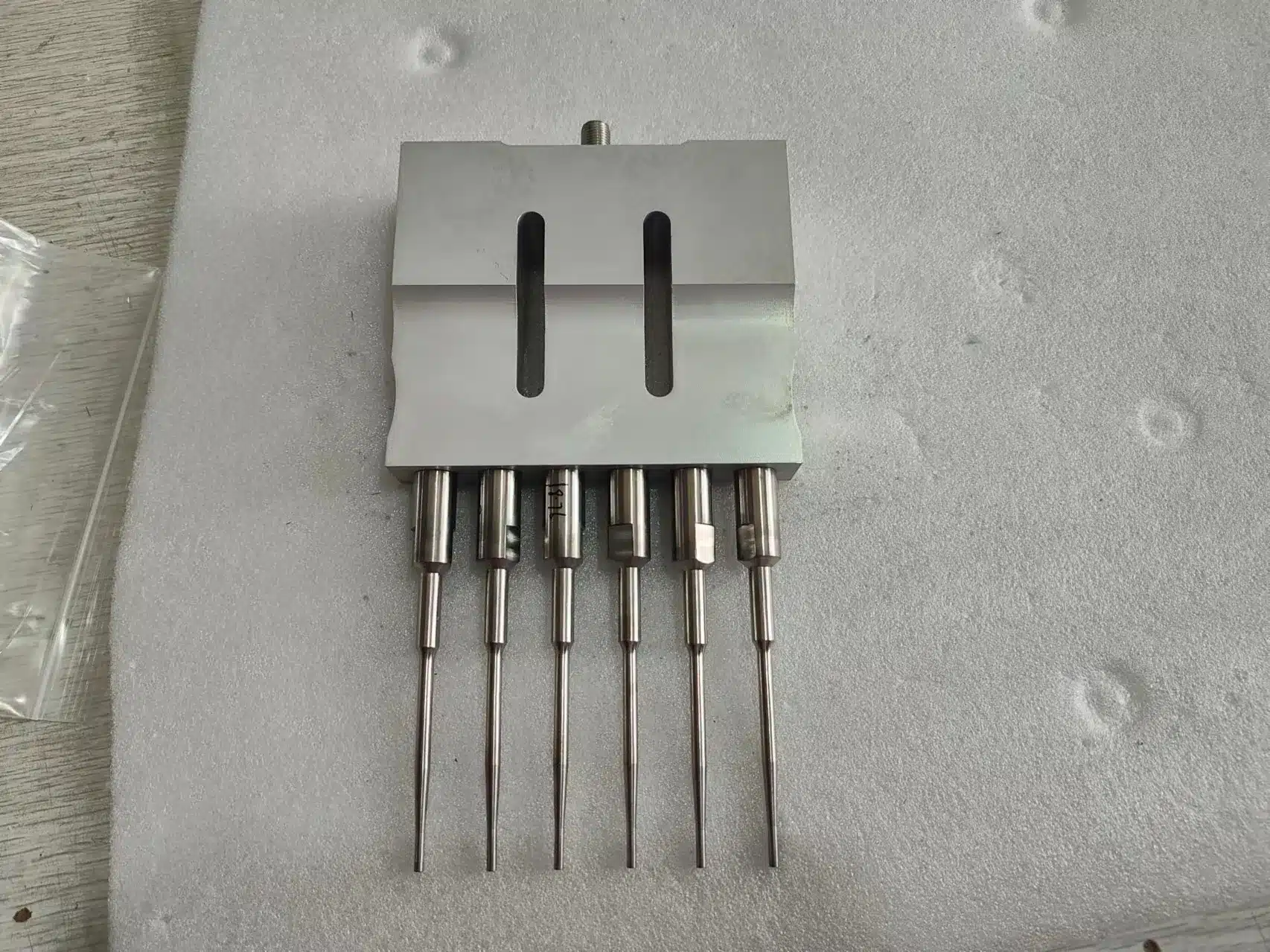

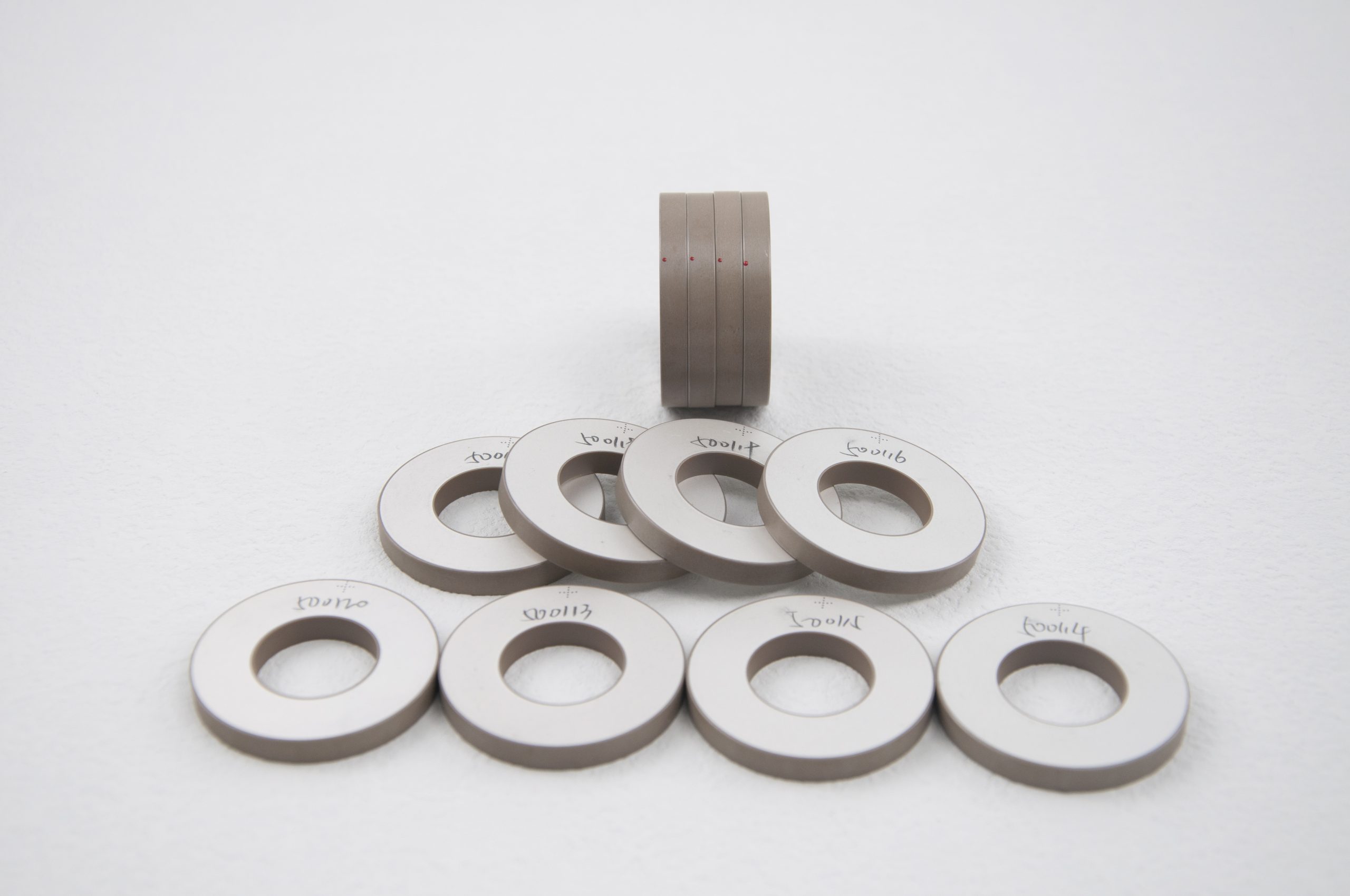

The cutter or blade, a critical component made from high-grade materials, resonates with the transducer’s vibrations, enabling it to slice through materials with ease and precision.

The machine’s body includes a control panel and a hydraulic lift system. Operators use the control panel to adjust settings and monitor machine performance. The hydraulic lift handles heavy materials, adjusting the height for optimal cutting.

Operating the Machine

To operate the machine, you place the material underneath and use a foot switch to start the cutting process. This method offers convenience and safety by enabling hands-free operation.

The control panel allows operators to adjust various parameters like cutting speed, blade depth, and ultrasonic vibration frequency. These adjustments ensure precise cuts tailored to the material.

Moreover, the control panel collects data during operation for statistical analysis. This data is invaluable for optimizing the cutting process, ensuring consistent quality, and reducing waste.

In conclusion, integrated ultrasonic cutter machines are essential in modern manufacturing processes. Their components and operational mechanics offer unmatched precision and efficiency, making them a vital tool in the industry.

More info, you can click here