What is the differences between mechanical homogenization and ultrasonic homogenization?

What is the differences between mechanical homogenization and ultrasonic homogenization?

Mechanical homogenization involves using physical force to break down and mix samples. This can be done using methods such as grinding, blending, or shearing. The goal of it is to achieve a consistent and uniform sample that is representative of the entire population.

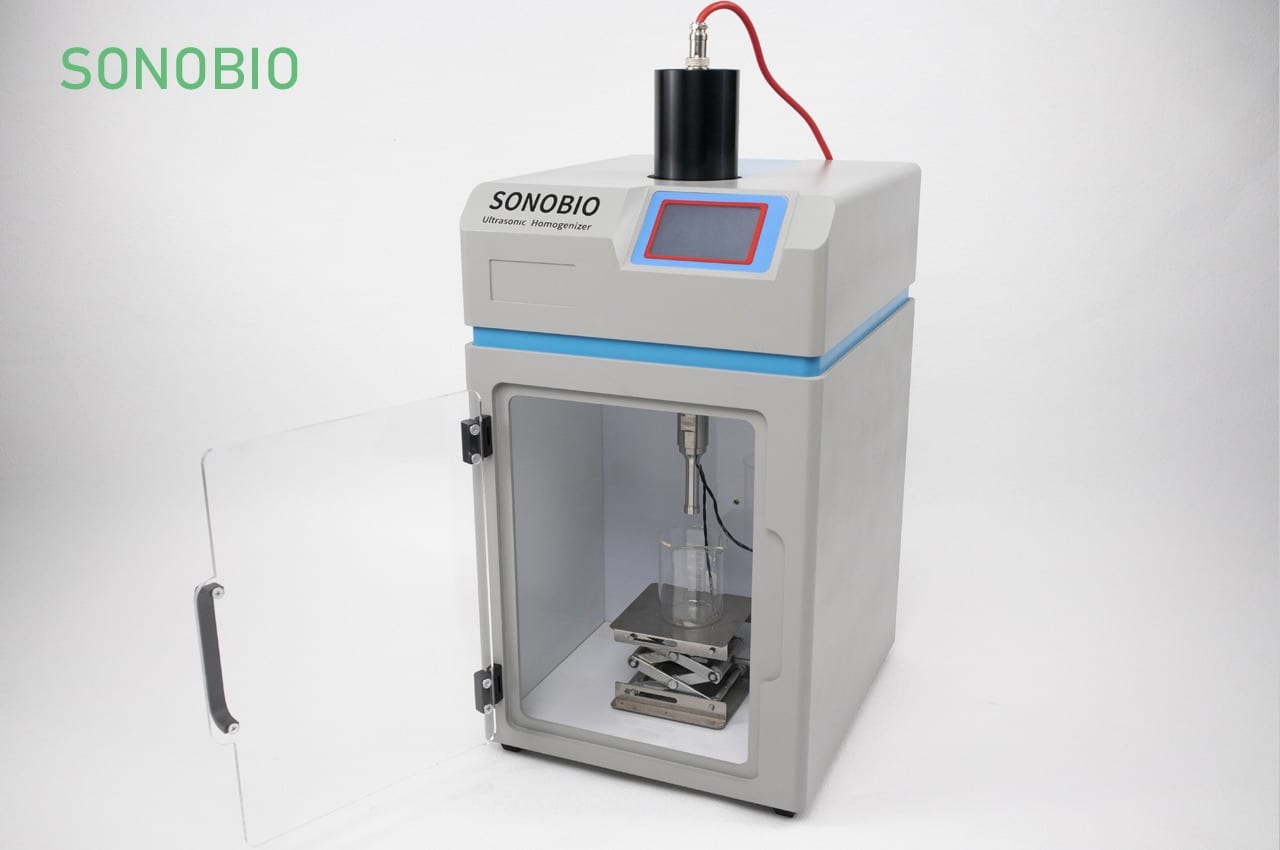

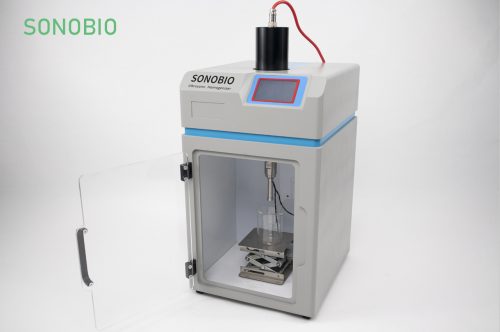

On the other hand, ultrasonic homogenization involves using high-frequency sound waves to break down and mix samples. The ultrasonic waves create small bubbles in the sample, which then collapse and create high-intensity shock waves. These shock waves cause the cells and particles in the sample to break apart and mix together.

Both mechanical and ultrasonic homogenization have their advantages and disadvantages. Mechanical is a more traditional method that is often easier to perform and can be used with a wider range of samples. However, it can also be more time-consuming and can sometimes damage delicate samples.

Ultrasonic homogenization, on the other hand, is a newer and more advanced method that can be used with smaller sample sizes and can achieve more precise results. It is also faster and gentler than mechanical, making it a popular choice in many fields.

Ultimately, the choice between mechanical and ultrasonic homogenization will depend on the specific needs of the application. Factors such as sample type, sample size, and desired outcome will all need to be considered when choosing the appropriate method.

In conclusion, understanding the principles and applications of both mechanical and ultrasonic homogenization is crucial for researchers and professionals in a variety of fields. By weighing the advantages and disadvantages of each method and selecting the appropriate technique for each application, researchers can achieve more accurate and consistent results.

Source: