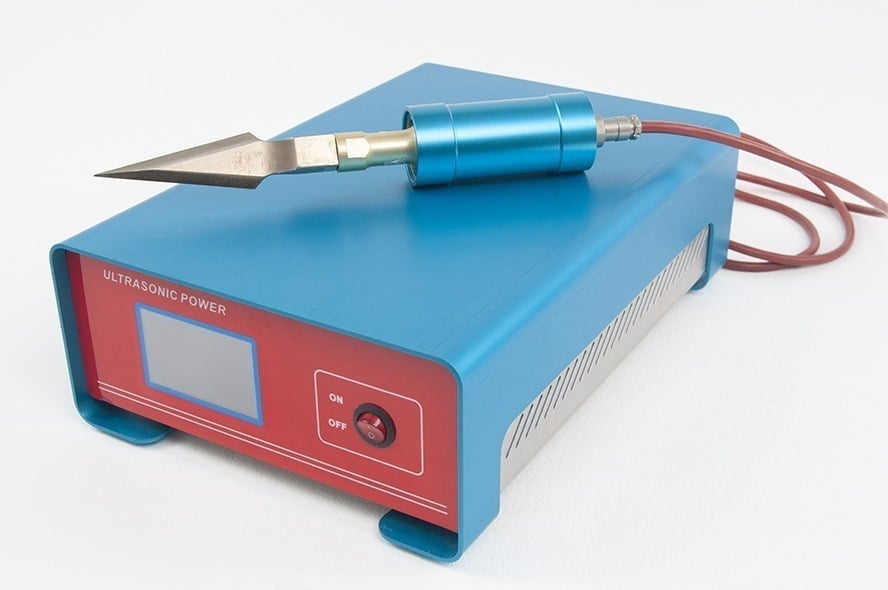

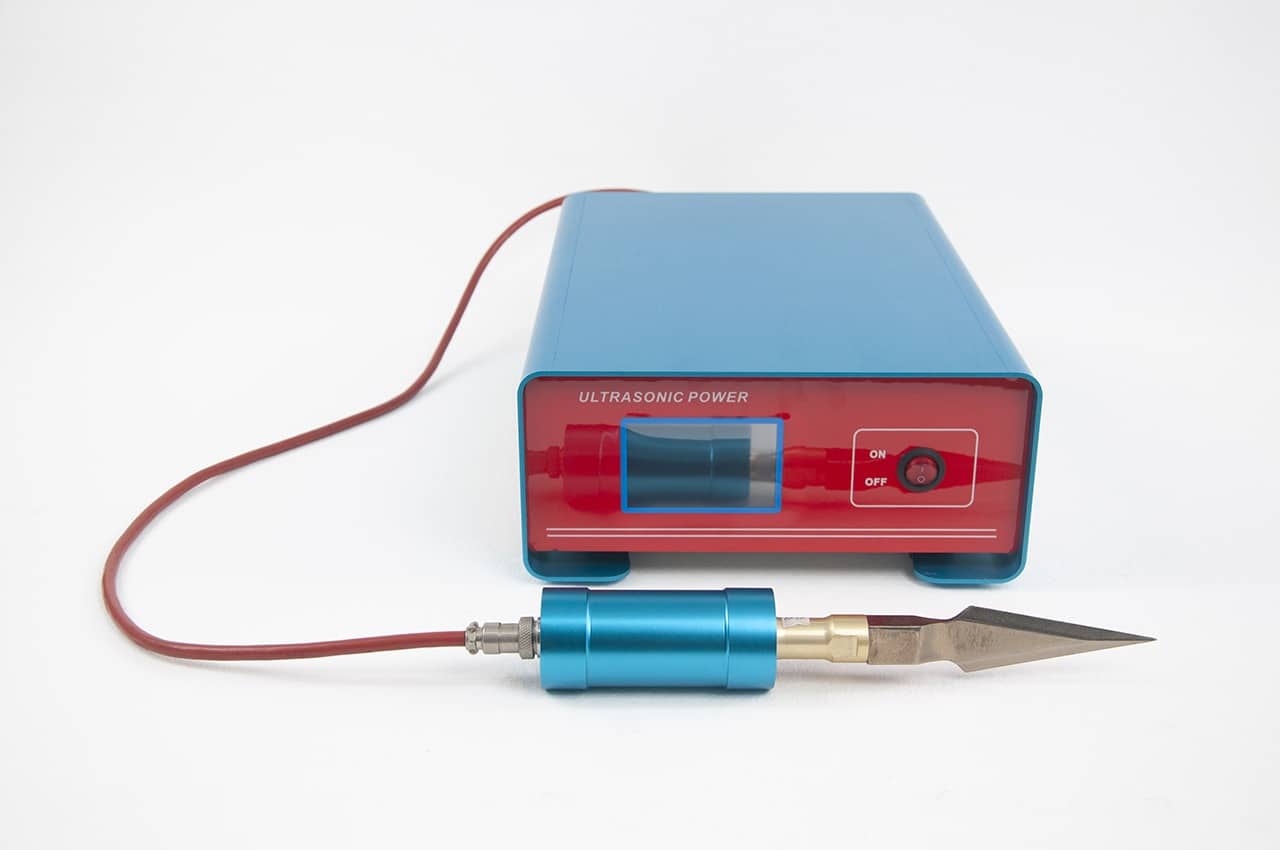

Ultrasonic Cutter Laboratory Industrial Ultrasound Plastic Cutting Knife Machine

$1,599.00

30% Off

APPLICATION: Honeycomb aluminum, ABS, PE, PVC, PC, acrylic, non-woven, neoprene, corrugated, plywood, fiberglass resin, cardboard, linen (linoleum), urethane, nylon, PP, etc.

PRINCIPLE: The ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. The material to be cut does not stick to the blade and does not collapse or break. It has obvious effect on cutting frozen, viscous and elastic materials.

FUNCTIONS: Automatic resonance point, automatic frequency sweep tracking in the frequency range of 19-26KHZ. Automatic amplitude compensation, which automatically works at the optimal frequency point and output point according to the fluidity of the sample. Independent on/off pulse with three modes of continuous use, pulse and timed continuous ultrasound.

NOTE: For knowing your requirements more clearly, please tell us the material type and thickness, and its shape.

Description

An ultrasonic cutter is a specialized tool utilizing high-frequency ultrasonic vibrations to cut, trim, or shape various materials. This versatile and precise cutting device finds applications in industries such as manufacturing, textiles, and food processing. Its fundamental principle involves converting electrical energy into mechanical vibrations, resulting in clean and efficient material cutting.

The core components of an ultrasonic cutter consist of a “transducer” responsible for generating ultrasonic oscillations and an “oscillator” that drives the transducer. The transducer incorporates piezoelectric elements, which, when subjected to an AC voltage at their characteristic frequency, induce mechanical vibrations. This resonance state causes the cutting blade to oscillate vigorously, allowing for precise and clean cuts.

Ultrasonic cutter come in various types to cater to specific industry needs. Some common types include:

- Handheld Ultrasonic Cutters: These portable units are manually operated and are used for intricate or smaller-scale cutting tasks. They offer flexibility and ease of use.

- Automated Systems: These systems are integrated into production lines and machinery, allowing for high-throughput and automated cutting in industrial settings. They are ideal for mass production.

- Ultrasonic Welding and Cutting Systems: Some ultrasonic cutters are combined with welding capabilities, enabling the simultaneous cutting and sealing of materials, making them suitable for applications like packaging.

For more product information and data, please check here. Click Here!For more usage methods and effects, you can check out our video. Click Here!

Additional information

| Weight | 6 kg |

|---|---|

| Dimensions | 40 × 30 × 20 cm |

| Delivery Time | 7 days after receiving payment |

| Packing Style | Inside Foam + Carton (Fedex /DHL Delivery) |

| Payment Term | Bank Transfer T/T for Order $500 & more, T/T or Paypal or West Union for Order less than $500 |

| Warranty Period | 1 Year Warranty, Free Replacement |

Only logged in customers who have purchased this product may leave a review.

Related products

Ultrasonic Food(Cake,biscuit)Cutter/Cutting Machine/Blade

$1,500.00 – $1,700.00

6% Off

Rotary Ultrasonic Cutter Laboratory Industrial Ultrasound Plastic Cutting Knife Machine

$1,799.00

28% Off

Reviews

There are no reviews yet.